Troubleshooting Guide

Engine/Motor and Drive Pulleys Alignment

Troubleshooting Guide

HDSdoc091108

4-12

4

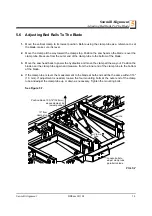

4.6

Engine/Motor and Drive Pulleys Alignment

1.

Install the drive belt.

2.

Use a straight edge to align the engine/motor pulley to the drive pulley. Also check that the engine

pulley is within 1/8" square with the drive pulley. Loosen the engine mounting bolts and rotate the

engine if necessary.

3.

Check front-to-back movement of the engine does not exceed 1/4". Tighten the motor mount

U-bolts if necessary.

4.

Engage the clutch handle and adjust the drive belt tension to 7/16" deflection with 10 lb. of force.

5.

Recheck the pulley alignment and engine squareness with the clutch handle engaged. Adjust if

necessary.

6.

Adjust the drive belt support to 1/4" (±1/32) from the belt while engaged.

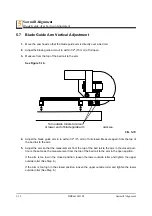

4.7

Power Feed Preliminary Test

This test will determine if the problem is a mechanical or electrical.

1.

Remove the drive belt from the power feed drive pulley.

2.

Turn the key switch to the ACC position. Put the carriage forward/reverse switch into the forward

position and turn the feed rate dial through all speeds. If the power feed motor runs properly at all

speeds, the problem is a mechanical one instead of an electrical one.

4.8

Power Feed Mechanical Test

1.

Remove the weight from the track rollers. They should turn smoothly and easily with very little play.

2.

Make sure the middle track cover is not bent or touching the top rail.

3.

Make sure the middle track oiler is free of sawdust buildup.

4.

Make sure the power feed chain is not stiff from rust. Also make sure the chain is not too tight.

5.

Check the power feed shaft. Visually inspect the bearings. The shaft should move neither in or out

nor side to side.

6.

Make sure the power feed chain cam bearing is not touching the main frame tube.

7.

Make sure there is no sap or rust on the rails.

8.

Make sure the block on the lower track roller assembly is not rubbing the lower rail. Also make

sure the track rollers are not too tight.

Summary of Contents for LT40 DH

Page 1: ......

Page 2: ......

Page 69: ...Maintenance Carriage Track Wiper Scrapers Maintenance HDSdoc091108 3 5 3 FIG 3 3 ...