Sawmill Alignment

Blade Installation And Alignment

5

5-4

HDSdoc091108

Sawmill Alignment

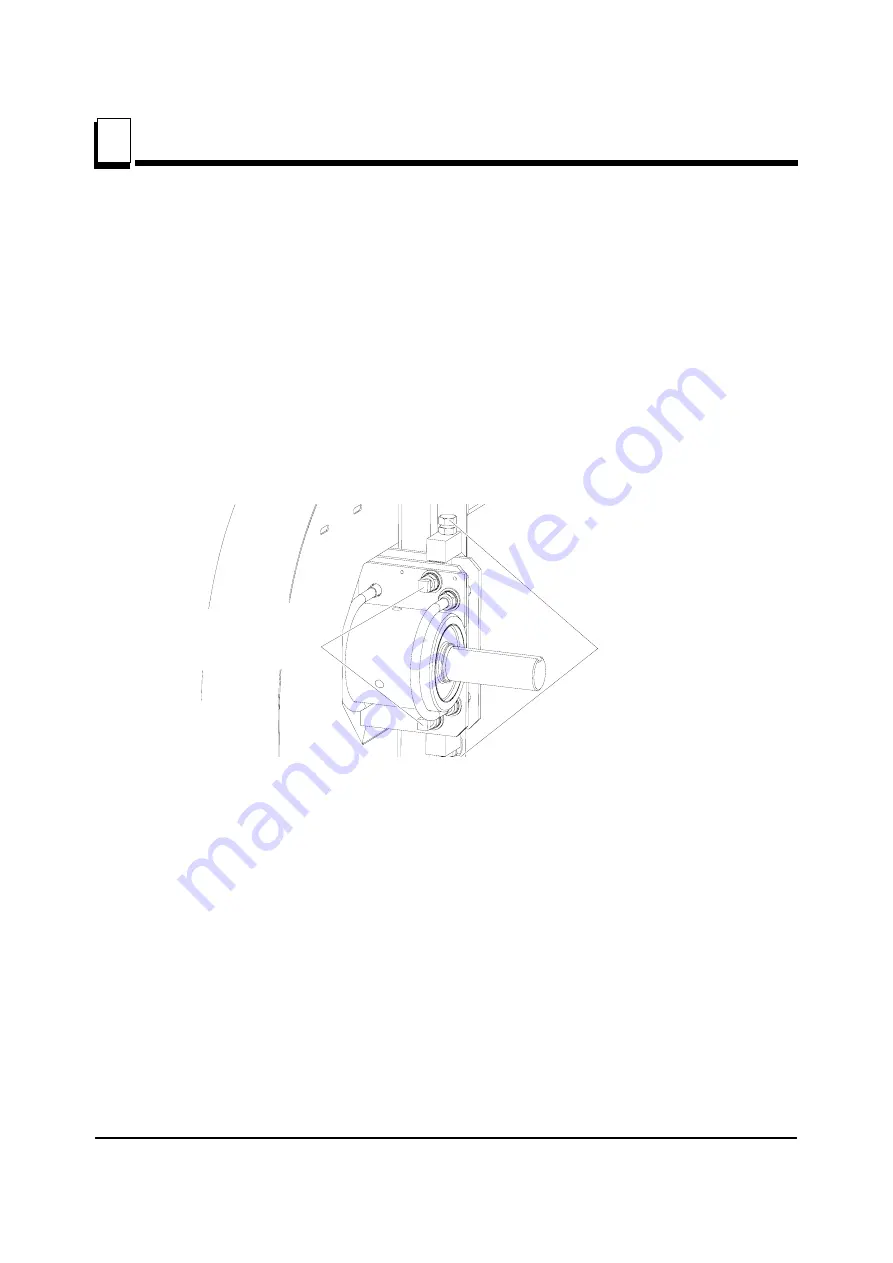

Adjustment with the cant control is usually all that is required to track the blade properly on both

blade wheels. The drive-side blade wheel will usually not have to be adjusted. If necessary, the

drive-side wheel can be adjusted as follows:

See Figure 5-3.

For horizontal adjustment, use the horizontal adjustment bolts. If the blade is run-

ning too far back on the drive-side blade wheel, locate the long U-bolt on the right which mounts

the bearing housing to the mounting plates. Loosen the hex nuts on the U-bolt (on the back side of

the back plate). Loosen the jam nuts on the horizontal adjustment bolts. Tighten the adjustment

bolts to spread the plates apart and bring the blade forward.

If the blade is running too far to the front, loosen the jam nuts on the horizontal adjustment bolts

and back the adjustment bolts out. Tighten the hex nuts on the long U-bolt (on the back side of the

back plate).

Be sure to tighten all nuts against the mounting plates when the adjustment is complete.

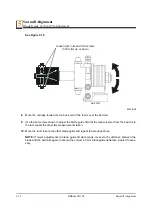

The vertical angle of the drive side wheel is factory-set and should not need to be adjusted. If

adjustment is needed use the vertical adjustment bolts. To tilt the wheel upward, tighten the top

bolt and loosen the bottom bolt. To tilt the wheel downward, tighten the bottom bolt and loosen the

top bolt.

FIG. 5-3

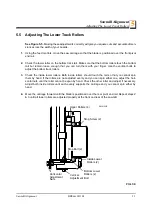

Vertical

Adjustment Bolts

SM0240

Horizontal

Adjustment Bolts

Summary of Contents for LT40 DH

Page 1: ......

Page 2: ......

Page 69: ...Maintenance Carriage Track Wiper Scrapers Maintenance HDSdoc091108 3 5 3 FIG 3 3 ...