Sawmill Alignment

Saw Head Slide Pad Adjustment

5

5-6

HDSdoc091108

Sawmill Alignment

1.

Raise the saw head to the top of the vertical mast and secure the saw head with a chain at the top,

or shim it underneath. Check the top set of four pads.The outer two pads should be touching the

mast rails. There should be a small gap (just wide enough to slide a business card through)

between one of the inner pads and the mast rail.

WARNING!

Always secure the cutting head with a chain or a

brace before adjusting the mast pads. The cutting head may fall,

causing severe injury or death.

2.

To adjust the spacing of the upper set of pads, lower the saw head until you can access the upper

slide pad adjustment bolts.

3.

Loosen the upper locking bolts and turn the adjusting bolt as necessary to provide the pad spacing

described in Step 1.

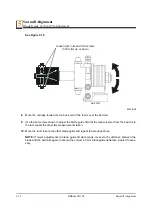

4.

Lower the saw head to the bottom of the vertical mast. Check the bottom set of four pads.

There should be a small gap between one of the outer pads and the mast rail. The gap should be

just wide enough to slide a business card through. The inner two pads should be touching the

mast rails.To adjust the spacing of the lower set of pads, raise the saw head until you can access

the lower slide pad adjustment bolts.

5.

Loosen the lower locking bolts and turn the adjusting bolt as necessary to provide the pad spacing

described in Step 4.

CAUTION!

Due to variations in the vertical mast, the pad spac-

ing may vary throughout the travel of the saw head. Check the

pad spacing at the top and bottom ends of the mast only. Pads

adjusted too tight will cause premature up/down motor failure.

Summary of Contents for LT40 DH

Page 1: ......

Page 2: ......

Page 69: ...Maintenance Carriage Track Wiper Scrapers Maintenance HDSdoc091108 3 5 3 FIG 3 3 ...