Safety & General Information

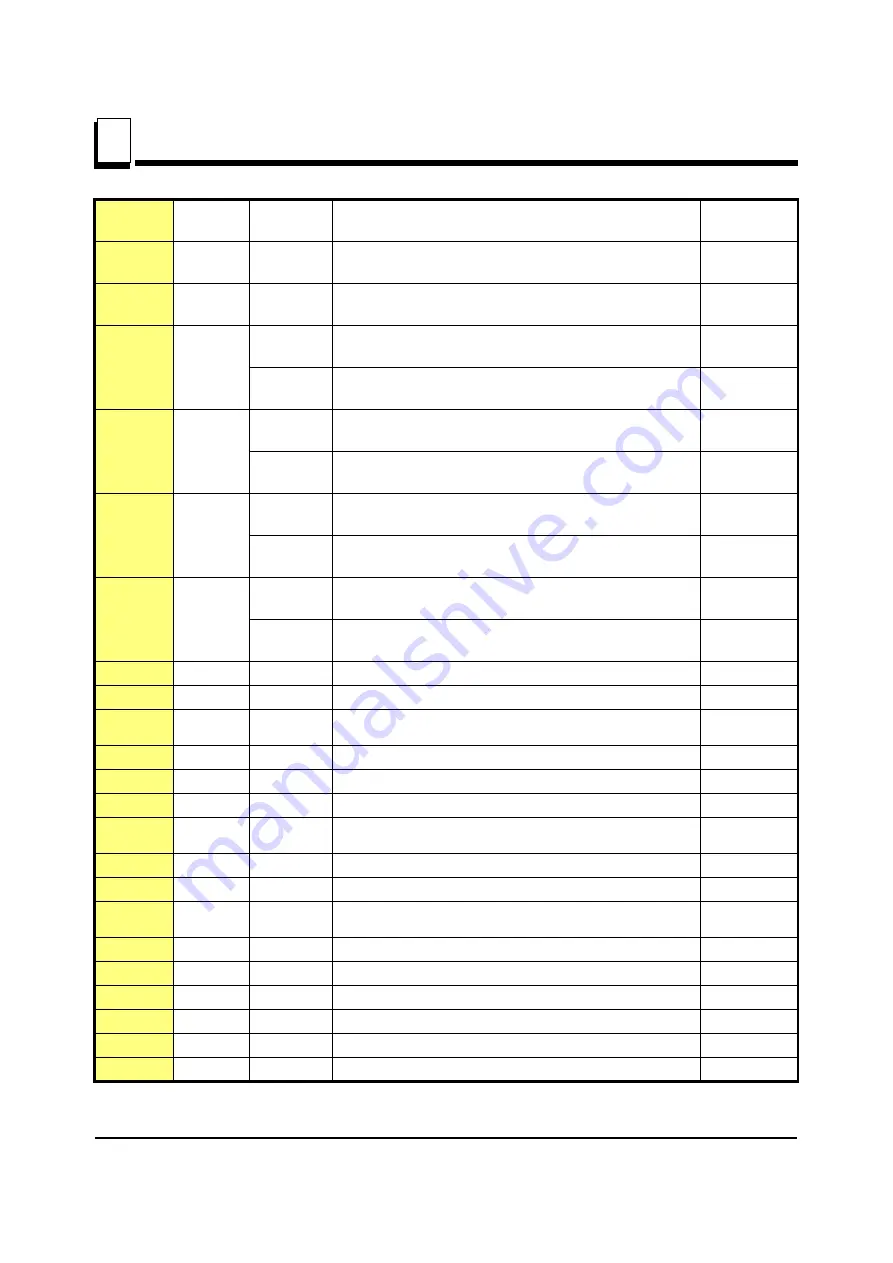

LT40 Series DH - Hydraulic Hoses

1

1-23

HDSdoc091108

Safety & General Information

H13

Green

1.58m

(62")

3/8” Loading Arm Branch Top

014797

H14

Yellow

1.6m

(63")

3/8” Loading Arm Branch Base

014798

H14

Yellow

1.8m

(71")

3/8” Loading Arm Branch Base

093329

H15

Blue

4.34m

(171")

3/8” Loading Arm Cylinder Top (LT40S)

087795

4.9m

(193")

3/8” Loading Arm Cylinder Top (LT40M)

087781

H16

Red

4.34m

(171")

3/8” Loading Arm Cylinder Bottom (LT40S)

087795

4.9m

(193")

3/8” Loading Arm Cylinder Bottom (LT40M)

087781

H17

Green

4.57m

(180")

1/4” Clamp Up (LT40S)

087796

5.1m

(202")

1/4” Clamp Up (LT40M)

087789

H18

Yellow

4.57m

(180")

1/4” Clamp Down (LT40S)

087796

5.1m

(202")

1/4” Clamp Down (LT40M)

087789

H19

WHITE

157"

3/8" FRONT LOG CLAMP, IN/OUT CYLINDER BOTTOM (A/DH5)

094778

H20

ORANGE

157"

3/8" FRONT LOG CLAMP, IN/OUT CYLINDER TOP (A/DH5)

094778

H21

RED

150"

3/8" FRONT LOG CLAMP, UP/DOWN CYLINDER BOTTOM

(A/DH5)

094779

H22

BLUE

150"

3/8" FRONT LOG CLAMP, UP/DOWN CYLINDER TOP (A/DH5)

094779

H23

WHITE

236"

3/8" REAR LOG CLAMP, IN/OUT CYLINDER BOTTOM (A/DH5)

094780

H24

ORANGE

236"

3/8" REAR LOG CLAMP, IN/OUT CYLINDER TOP (A/DH5)

094780

H25

RED

220"

3/8" REAR LOG CLAMP, UP/DOWN CYLINDER BOTTOM

(A/DH5)

094781

H26

BLUE

220"

3/8" REAR LOG CLAMP, UP/DOWN CYLINDER TOP (A/DH5)

094781

H27

PLAIN

15"

3/8" VALVE TO OIL FLOW CONTROL VALVE (A/DH5)

094782

H28

PLAIN

21"

3/8" HYDRAULIC PUMP W/MOTOR TO OIL FLOW CONTROL

VALVE (A/DH5)

087775

H29

RED

1,50

1/4" FIRST CLAMP, UP/DOWN CYLINDER BOTTOM (AH7)

095211

H30

BLUE

1,50

1/4" FIRST CLAMP, UP/DOWN CYLINDER TOP (AH7)

095211

H31

RED

4,00

1/4" SECOND CLAMP, UP/DOWN CYLINDER BOTTOM (AH7)

095212

H32

BLUE

4,00

1/4" SECOND CLAMP, UP/DOWN CYLINDER TOP (AH7)

095212

H33

RED

7,70

1/4" THIRD CLAMP, UP/DOWN CYLINDER BOTTOM (AH7)

095213

H34

BLUE

7,70

1/4" THIRD CLAMP, UP/DOWN CYLINDER TOP (AH7)

095213

TABLE 1-7

Summary of Contents for LT40 DH

Page 1: ......

Page 2: ......

Page 69: ...Maintenance Carriage Track Wiper Scrapers Maintenance HDSdoc091108 3 5 3 FIG 3 3 ...