Setup & Operation

Preparing The Sawmill For Towing

2

2-29

HDSdoc091108

Setup & Operation

Never use flammable fuels or liquids. If these types of liquids are

necessary to clean the blade, remove it and clean with a rag. Fail-

ure to do so may result in serious injury or death.

Before removing the blade, engage the clutch/brake lever. Let the blade spin with water running on

it for about 15 seconds. This will clean the blade of sap buildup. Wipe the blade dry with a rag

before storing or sharpening.

If you are sawing in freezing temperatures, remove the water lube bottle from the sawmill when

done sawing and store it in a warm place. Blow any remaining water from the water lube hose.

To remove water from the water valve on Super models, turn the key switch to accessory (#3), turn

the feed rate knob down to ‘0’ and place the feed switch in the forward position. Blow any remain-

ing water from the water lube hose and valve. Return the forward/reverse switch to neutral and

turn the key switch to off (#0).

2.20 Preparing The Sawmill For Towing

The Wood-Mizer trailer package makes transporting your sawmill easy and convenient. To get

your sawmill ready for towing, follow these instructions.

CAUTION!

If the weight of the sawmill exceeds 3,000 lbs (1361

Kg) for any reason, an auxiliary braking system (such as electric

brakes) must be used. Failure to do so may result in severe

machine damage.

1.

Move the saw carriage to the front end of the sawmill. Raise the rear outriggers.

2.

Move the clamp all the way in toward the main bed frame tube.

CAUTION!

Move the hydraulic clamp and turner to provide max-

imum ground clearance before towing. Failure to do so may result

in damage to the sawmill.

3.

Use the hydraulic controls to raise the log turner and loader as high as they will go. Manually lift

the loader and hook the loader chain to the elbow of the turner. Use the hydraulic turner lever to

lower the turner until the chain is tight. Push the loader lever down to bring the loader arm chan-

nels up to the loader.

4.

Move the carriage forward to the travel position over the rear bed rail.

5.

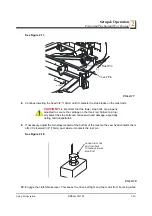

Position the hole in the saw head over the travel rest pin.

6.

Lower the saw head until it is seated firmly on the rest pin.

7.

Secure the rest pin in the vertical position with the locking pin.

Summary of Contents for LT40 DH

Page 1: ......

Page 2: ......

Page 69: ...Maintenance Carriage Track Wiper Scrapers Maintenance HDSdoc091108 3 5 3 FIG 3 3 ...