Maintenance

Hydraulic System

5

5-20

50HD07doc072310

Maintenance

5.12 Hydraulic System

WARNING!

Disconnect and lockout power before perform-

ing any service to the electrical system. For battery-pow-

ered equipment, disconnect the negative battery terminal

cable. Failure to do so may result in injury and/or electrical

system damage.

1.

Check the hydraulic fluid level every fifty hours of operation. Add fluid as necessary. The

level in the hydraulic pump should be 3/4" (19mm) from the top with all cylinders col-

lapsed.

If humidity is a problem or the mill is used outside in humid weather, drain and replace

two quarts (.95 liters) of fluid every six months. This will drain any accumulated water and

help prevent pump failure due to water ingestion. It also will prevent excessive fluid wear

and allow the fluid to maintain its hot end performance. If humidity is not a problem, drain

and replace one gallon (3.8 liters) of fluid every year to prevent fluid wear.

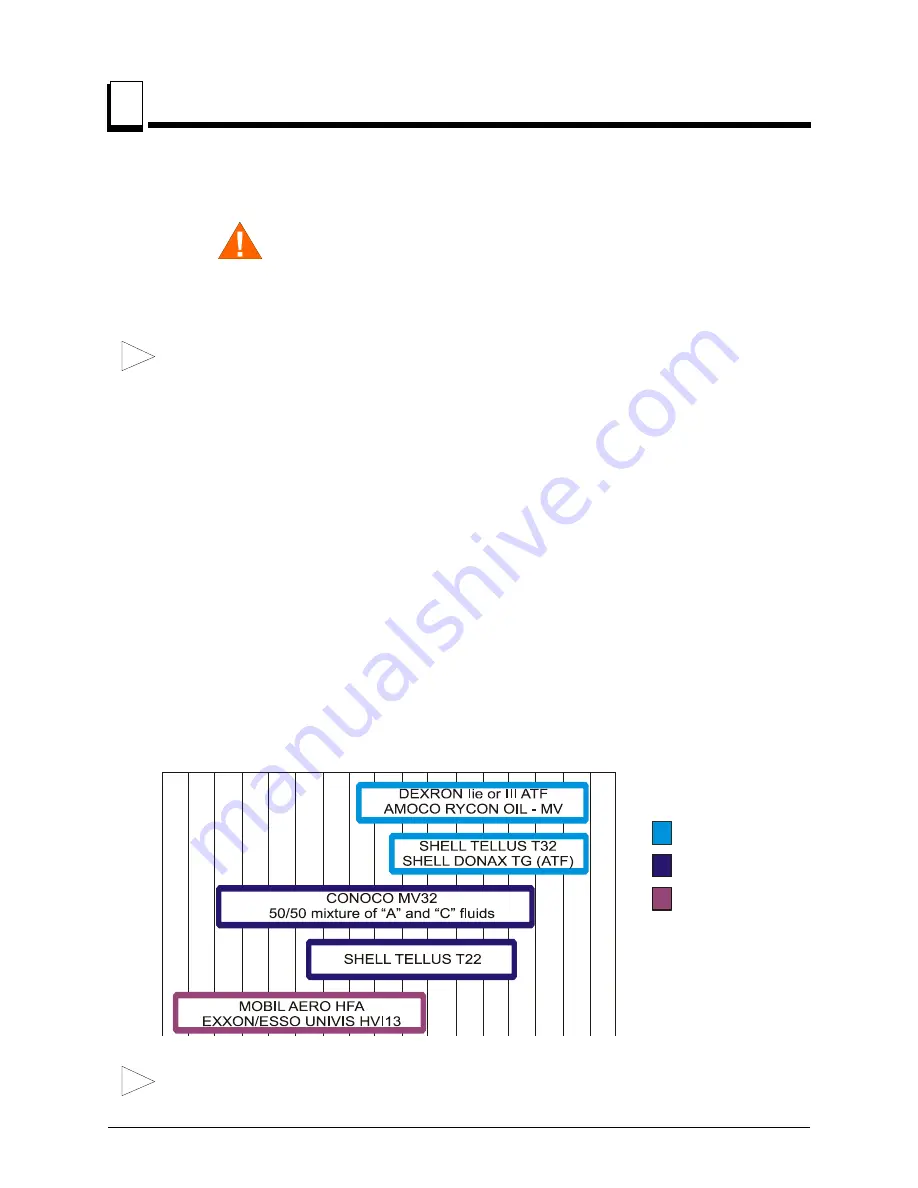

See Figure 5-11.

If you are operating in temperatures -20° to 100° F (-29° to 38° C), use

an all-weather hydraulic fluid such as Conoco MV32. For alternate fluids and/or other

temperature ranges, refer to the chart below. Operating above the recommended temper-

ature range of a fluid could result in excessive pump wear. Operating below the recom-

mended temperature range could result in reduced hydraulic cylinder speed. To change

fluid types, replace one gallon of the current fluid with one gallon of the alternate fluid.

2.

Replace the hydraulic system cartridge filter every 500 hours of operation.

FIG. 5-11

50

120°

49°

40°

5°

80°

27°

0°

-18°

100°

38°

20°

-7°

60°

16°

-20°

-29°

110°

44°

30°

-1°

70°

21°

-10°

-23°

90°

32°

10°

-12°

50°

10°

-30°

-35°

F

C

Level A Fluid

Level B Fluid

Level C Fluid

HY

DRAUL

IC

FLU

ID

TEMPERATURE

500