Maintenance

Miscellaneous

Maintenance

60HD-R04doc112210

5-12

5

5.7

Miscellaneous

WARNING!

Before performing service near moving parts

such as blades, pulleys, motors, belts and chains, first turn

the key switch to the OFF (#0) position and remove the key.

If the key is turned on and moving parts activated, serious

injury may result.

1.

Oil all chains with Dexron III ATF every fifty hours of operation.

CAUTION!

Do not use chain lube. It causes sawdust

buildup in chain links.

2.

Apply a thin film of a NLGI No. 2 grade lithium grease to the blade guide arm every fifty

hours of operation to help prevent it from rusting.

3.

Adjust the blade guide arm drive chain as necessary to prevent the arm from slipping. To

adjust the chain, loosen the blade guide arm motor mounting plate bolts and slide the

motor to take slack out of the chain.

4.

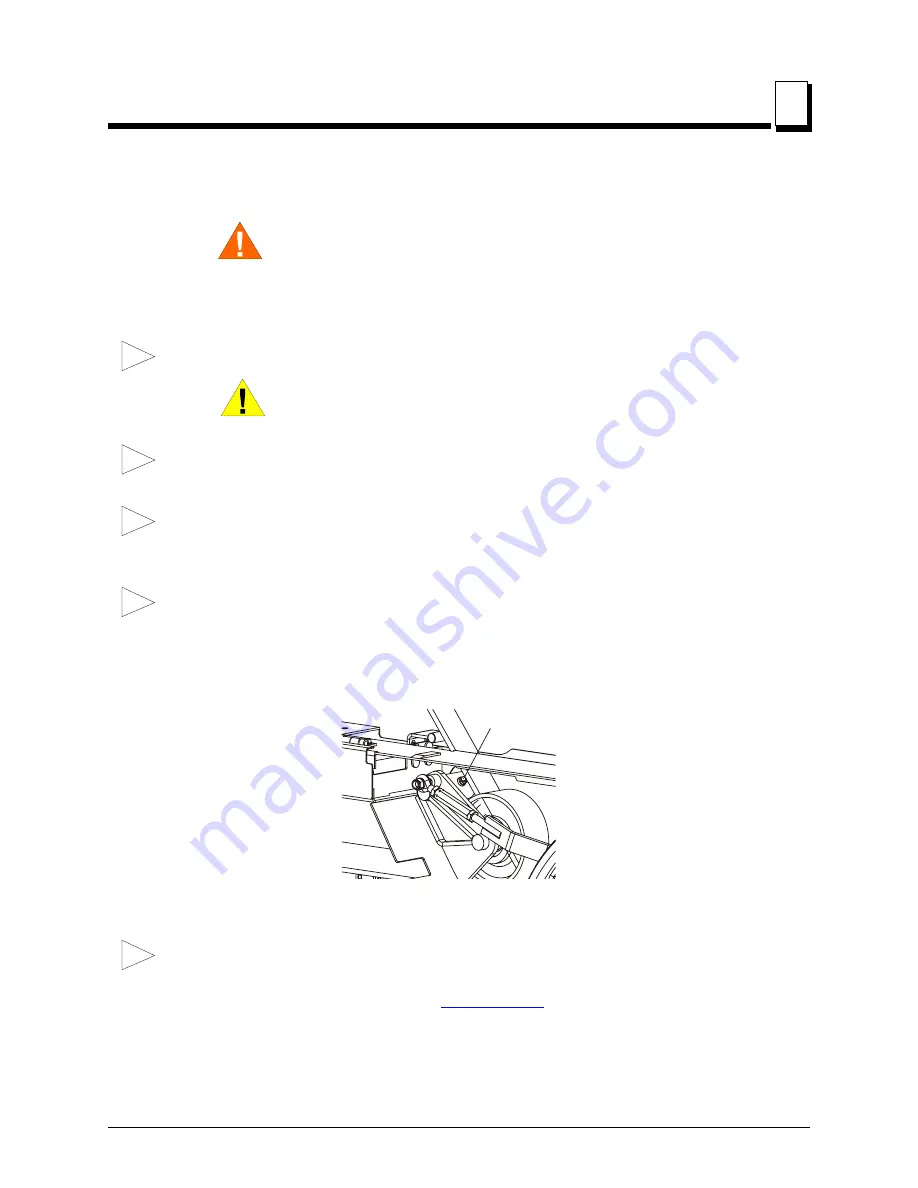

Apply NLGI No. 2 grade lithium grease to the drive belt tensioner pivot every fifty hours of

operation (grease fitting after 4/06).

See Figure 5-4.

5.

Grease the clamp mechanism, loading arm and side support pivots with a NLGI No. 2

grade lithium grease every fifty hours of operation.

6.

Check the mill alignment every setup (

7.

Make sure all safety warning decals are readable. Remove sawdust and dirt. Replace any

damaged or unreadable decals immediately. Order decals from your Customer Service

Representative.

FIG. 5-4

50

50

AR

50

Grease

Fitting

600005-20

50