Sawmill Operation

Loading, Turning And Clamping Logs

Sawmill Operation

60HD-R04doc112210

4-3

4

4.2

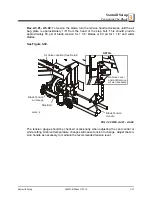

Loading, Turning And Clamping Logs

To Load Logs

1.

Move the saw carriage to the front end of the frame.

CAUTION!

Before loading a log, be sure the cutting head is

moved far enough forward so the log does not hit it. Failure

to do so may result in machine damage.

CAUTION!

Be sure the log clamp, pivot rails, turning arm

and toe boards are adjusted out of the path of the log

before loading a log onto the bed. Failure to do so may

result in machine damage or cause misalignment.

2.

Raise the side supports on the sawmill bed to prevent the log from falling off the side of

the bed.

3.

Use cant hooks or loading equipment to move the log to the foot of the loading arms.

4.

Roll the log onto the loader so that it is approximately centered with the sawmill bed. The

log turner will operate much easier if the log is centered on the sawmill bed.

DANGER!

Keep all persons out of the path of moving

equipment and logs when operating sawmill or loading and

turning logs. Failure to do so will result in serious injury.

5.

Start the engine and raise the loader lever to raise the log onto the sawmill bed. Simply let

the loader rise until the log rolls onto the mill bed.

6.

Lower the loading arm. Leave the loading arm about halfway up while squaring the log.

This will stop the log from rolling off the side of the mill.

WARNING!

Always leave loading arm halfway up while log

is on sawmill bed. Failure to do so may result in serious

injury or death.

NOTE:

Logs also may be loaded onto the mill with a tractor or other equipment specifi-

cally designed for that purpose.

7.

Raise the clamp up/down lever to raise the clamp up to prevent the log from rolling off the

bed.