Setup

Assemble the bed sections

3-10

LX25 4/8/21

Setup

3

SECTION 3 SETUP

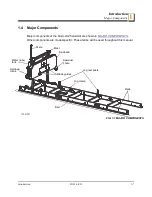

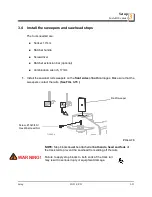

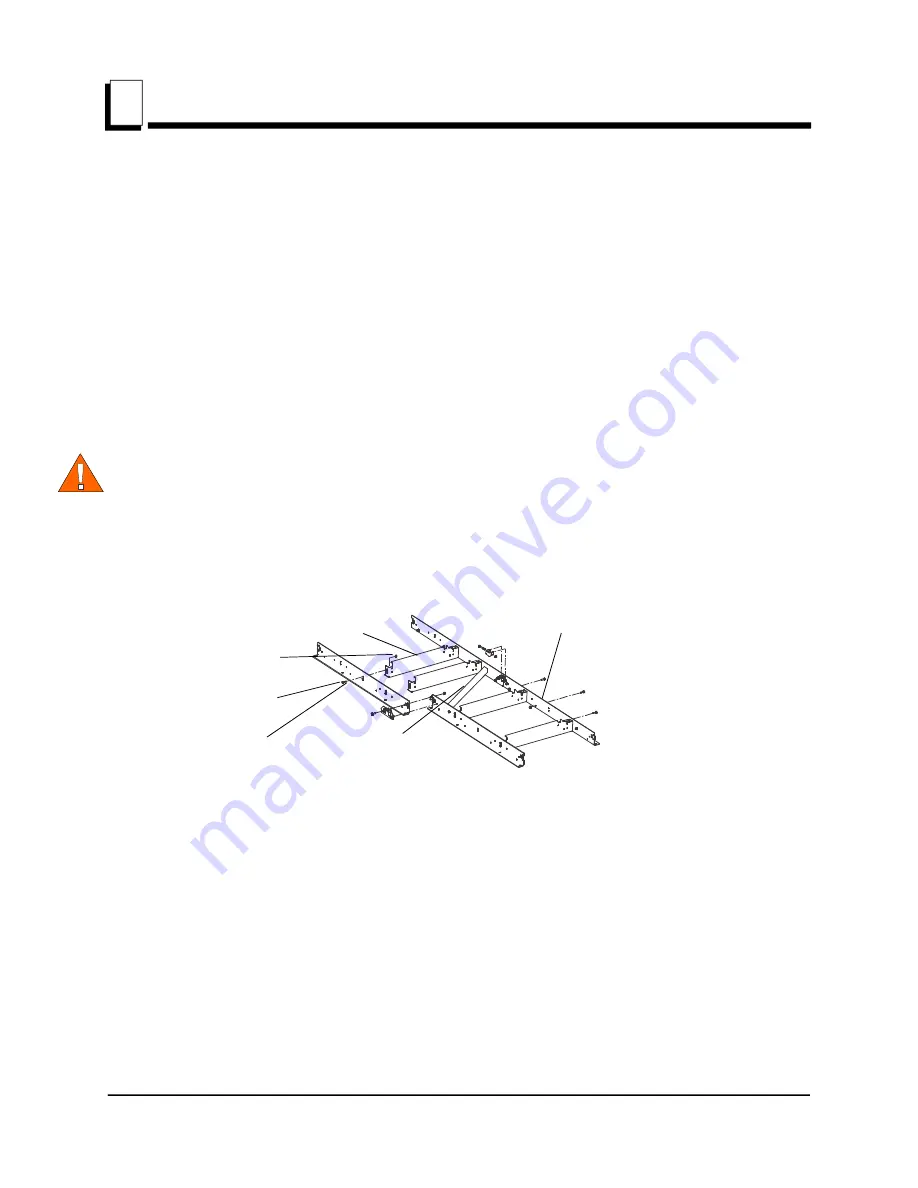

3.1 Assemble the bed sections

The tools needed are:

Socket, 17mm

Ratchet handle

Ratchet extension bar (optional)

Combination wrench, 17mm

Assemble the bed on firm, level ground. Failure to do so may

cause the sawhead to tip, causing serious injury or death.

1.

Assemble all of the bed sections using track rails and cross rails, and one cross member

where each bed section joins together.

a.

Attach two cross rails per bed section. Make sure to place the cross rails closer

together, leaving room for the sawhead assembly, as shown.

b.

Attach the track rails to the cross rail. Make sure all of the cross rails face the

NOTE:

Do not attach the catch rails at this time!

FIG. 3-1

WARNING!

TDLX2503-03

Track Rails

Cross Rails

Cross Member

Bolt, M10-1.5x30 HH

Class 8

Nut, M10-1.5 Flanged

Nylon Lock

Washer, M10 Flat