SETUP & OPERATION

Planning / Thicknessing

EGdoc052521

3-7

3

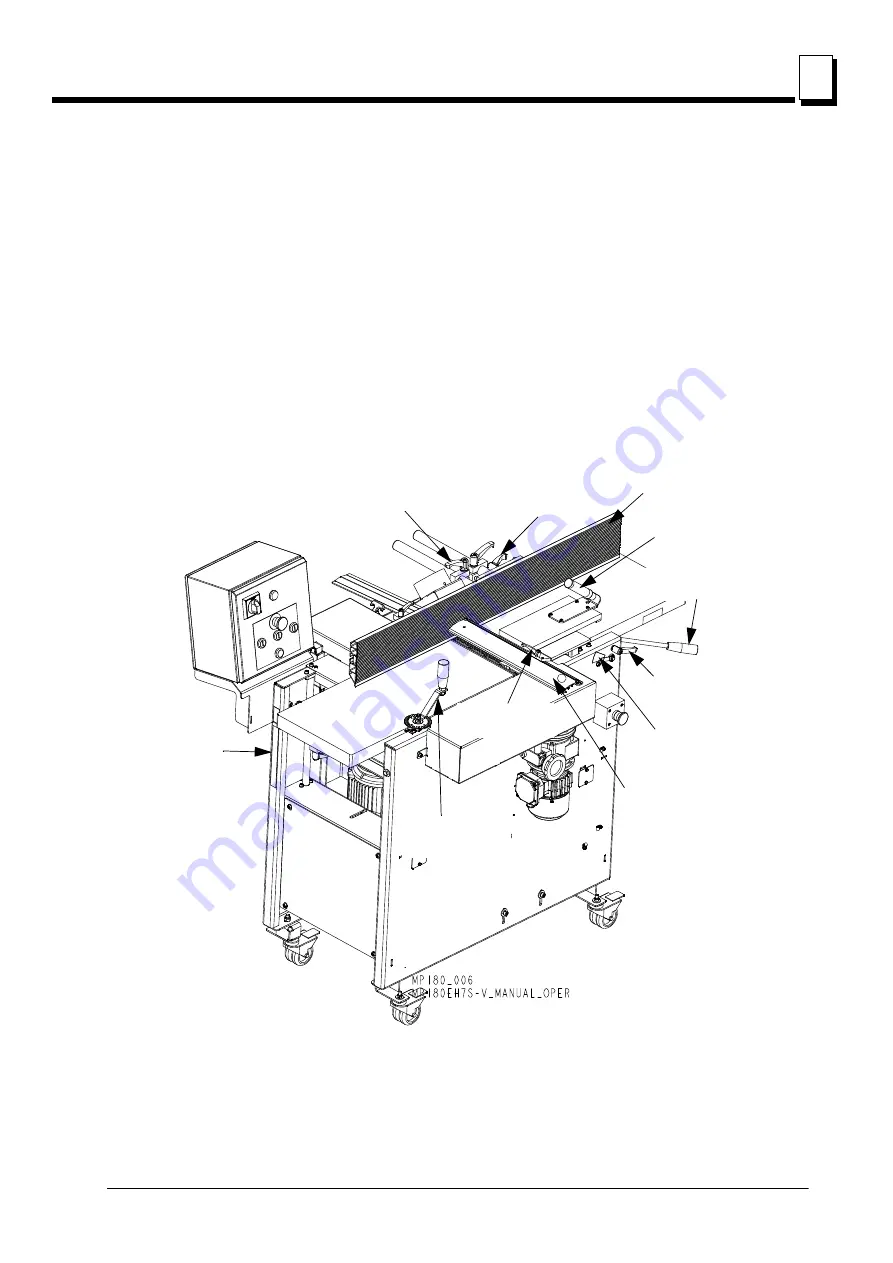

SETTING THE MACHINE FOR PLANING/THICKNESSING

The top cutter is fixed to the housing and hung at both ends. Two planing knives are mounted in two

cutter sockets (planer knife 410 mm HSS).

The

planing

thickness is adjusted with the planing (top) table handle (A). After performing the

adjustment, lock the table position with the locking handle (B). The set thickness can be read

on the scale (C). Set the protective guard (E) so it covers the workpiece from the upper side (for

the workpiece height up to 75mm). When angle-planing (or the workpiece is higher than

75mm), the protective guard should be completely lowered and set that the workpiece fit

between the guard (E) and the fence (G). The planing angle (0-45 degrees) can be adjusted

after loosening the angle locking handle (H). The fence position can be changed after

loosening the fence locking handles (I).

See figure 3-6.

FIG. 3-6 MP180

Upper Table Height

Scale (C)

Upper Table Height

Adjustment Handle(A)

Upper Table Locking

Handle (B)

Protective Guard (E)

Pusher (D)

Fence (G)

Guard Locking

Handle (F)

Angle Locking

Handle (H)

Fence Locking

Handles (I)

Lower Table

Height Adjusting

Handle (J)

Lower Table

Height Scale (K)