SETUP & OPERATION

Chain transmission with trapezoidal thread adjustment

3

3-14

EGdoc052521

3.2.4 Chain transmission with trapezoidal thread adjustment

The chain used to raise and lower the table must not be slack, but needs to be tensioned enough so

that its teeth mesh correctly.

The chain tension is adjusted with the nut located on the machine base, under the outfeed table.

Do not adjust the chain tension when the table is raising or lowering. In this case incorrect chain

tension can mean that the chain has been disconnected.

3.2.5 Variable speed motor manual (optional equipment)

WARNING!

Do not turn the feed speed adjustment knob when the

feed is off or the material is planing/moulding.

ASSEMBLY (IF VARIABLE SPEED MOTOR IS MOUNTED IN PLACE)

Mount the feed motor on the last feed roller. Be sure the torque is constant. Use the lock screw to

secure the motor on the roller.

SETTING THE FEED SPEED

To set the feed speed, use the knob located on the feed gear. To increase the speed, turn the knob

right, to decrease - turn it left.

MAINTENANCE

Fluid should be visible in the fluid inspection window. The fluid level should be checked when the

feed gear is not working.

The fluid should be refilled when it is not visible in the inspection window. Use oil for automatic

gearboxes or compatible oil according to the table below.

The variator is filled with AGIP BLASIA 32 at the factory and normally does not require oil change

during its life.

The worm gear oil does not normally need changing or topping up during gear life.

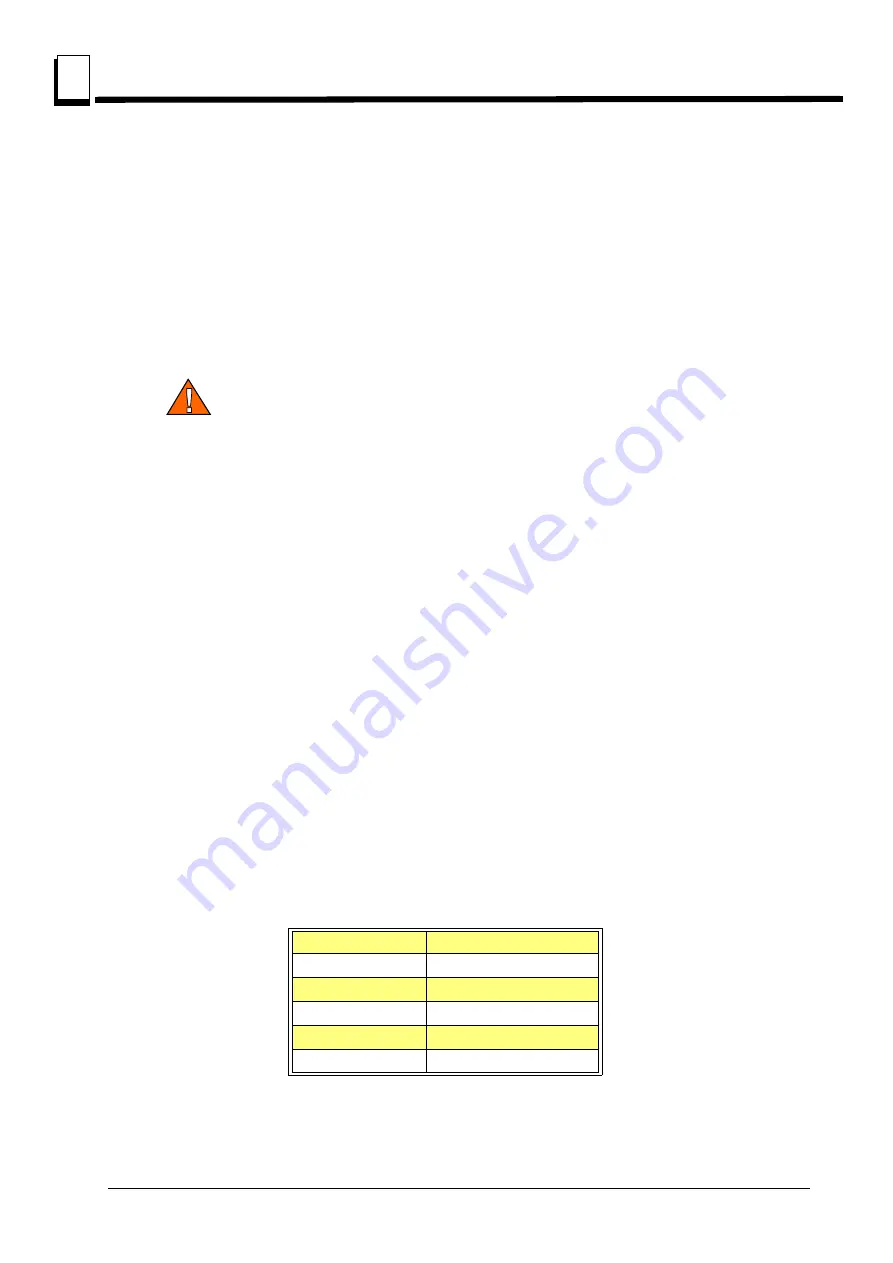

See table 3-2.

Recommended oil types

AGIP

BLASIA 32

SHELL

A.T.F DEXRON

ESSO

A.T.F DEXRON

MOBIL

A.T.F 220

CASTROL

DEXTRON II

BP

AUTRAN DX

TABLE 3-2