Cascade Gas-Fired Rotisserie & Charbroiler

Installation and Operation Manual

13

An ongoing program of product improvement may require us to change

specifications without notice.

WS-GFR-MB, Revised November 2014.

Doc no: M0050.01

info@woodstone-corp.com

or visit

woodstone-corp.com

wood stone corporation

1801 w. bakerview rd.

bellingham, wa 98226 usa

tf. 800.988.8103

t. 360.650.1111

f. 360.650.1166

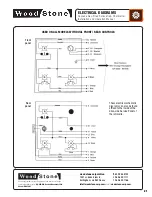

GAS INFORMATION

View from the Service Panel

showing the gas control

valves

The Cascade Rotisserie is equipped with a 1-inch FNPT gas inlet connection� Have a licensed gas installer provide the hook-up and

test all fittings and pipe connections for leaks� Use approved gas leak detectors (soap solutions or equivalent) over and around the

fittings and pipe connections�

DO NOT USE A FLAME TO TEST FOR LEAKS!

Wood Stone recommends that a manual, individual appliance shutoff valve be supplied, located between the rotisserie and the main

gas supply, and be left readily accessible�

ROTISSERIE BURNER PRESSURE TESTING

There are (2) pressure test ports (one for each burner), located on the respective valves� The valve outlet pressures have been

adjusted and tested at the factory� A variety of factors can influence these pressures, so be sure to test the valve outlet pressures

and adjust the valves as necessary to achieve the suggested pressures�

NOTE:

The gas valves are shipped in the ON position�

NATURAL GAS

The factory specified individual valve outlet pressures for models equipped to burn Natural Gas is 4" W�C� The maximum hourly

Natural Gas input rate for the Wood Stone Cascade Rotisserie (WS-GFR-MB-NG) is 175,000 BTU/hr�

PROPANE (LP)

The factory specified individual valve outlet pressures for models equipped to burn Propane (LP) is 8" W�C� The maximum hourly

Propane input rate for the Wood Stone Cascade Rotisserie (WS-GFR-MB-LP) is 185,000 BTU/hr�

This appliance requires no modifications or adjustments for use at high altitudes.

Infrared (IR) Burner (SV-1)

Radiant Flame Burner (SV-2)

GAS INFORMATION