-12-

- Turn spring pin (A) approximately one-half revolution

clockwise and hold.

- Insert guard post into hole in table. Make sure spring pin

rests and places pressure against the table casting.

FIG. 5.6.

5.6 INSTALLING THE CUTTERHEAD GUARD

5.7 INSTALLING THE INFEED TABLE LEVER

(This part may have been pre-installed at the

factory.)

5.8 OUTFEED TABLE ADJUSMENT KNOB

- Locate the Infeed Table Lever and install into the

threaded hole of the Lifting Assembly under the Infeed

Table.

- Once the Infeed Table Lever is fully threaded into the

Lifting Assembly tighten the 19MM locking nut to secure

into position. FIG. 5.7.

- Locate the Outfeed Table Adjustment Knob, Allen Cap

Screw M6 x 12mm and 6mm Flat Washer.

- Insert the Outfeed Table Adjustment Knob onto the

square receiver of the Table Adjustment Screw Shaft

located under the Outfeed Table. Secure using the Allen

Cap Screw M6 x 12mm and 6mm Flat Washer. FIG. 5.8

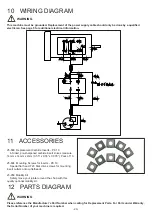

5.5 DUST PORT ASSEMBLY

A Dust Port (A) is supplied with the jointer to help connect

it to a standard 4 inch vacuum hose.

Hardware needed:

M5 x 10 Phillips Head Screw (x4)

M5 Flat Washer (x4)

- Tighten the two upper Screws (B) with a Phillips

screwdriver, and tighten the two lower Screws (C) with

a Phillips screwdriver when the dust port is in proper

location. FIG. 5.5.

It is extremely important that a dust collection system

is used with this jointer to eliminate harmful airborne

dust, prevent the build-up of chips that may jam the

cutterhead, and to keep the working area clean of

debris. Make sure all connections are secure and

your dust collector is turned on before any milling of

lumber is done.

However, if you do not plan to use a dust collector,

then there is no need to attach this dust port to the

jointer. Chips ejected from the operating machine

should be collected and disposed of immediately to

keep the area clean and to avoid accidents.

FIG.5.5

FIG.5.6

FIG.5.7

FIG.5.8

CAUTION