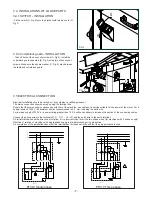

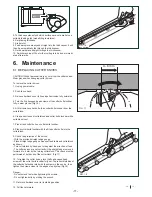

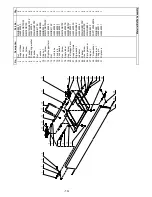

- Planing the face of a plank or workpieces up to 75 mm

thick: lower cutterblock cover from top onto workpiece. Adjust

cutterblock cover so that the undermentioned distances are not

exceeded in any position:

rear edge (A, Fig.14) – workpiece max. 3 mm;

front edge (B, Fig.14) – workpiece max. 2 mm.

6. Start motor.

7. Feed workpiece straight across the infeed table holding your

fingers close together, guiding the workpiece with the palm of

your hands. Exert downward pressure on the workpiece only in

the infeed table area.

8. Switch machine off if no further cutting is to be done

immediately afterwards.

max. 3 mm

max. 2 mm

A

B

FIG. 14

5.3. THICKNESS PLANER MODE

Note: Thickness planing is used to reduce a workpiece with one

already surface planed surface to a desired thickness.

- The workpiece is run through the thicknesser.

- The surface already planed flat rests on the thicknesser bed.

- The workpiece is cut on the upper side.

- The feed direction of the workpiece is exactly opposite than

with surface planing.

Workpiece dimensions

- Length: min. 200 mm; for workpieces over 1500 mm use a

second person for support.

- Width: max. 305 mm.

- Thickness: min 6 mm; max. 200 mm.

Note: The max. depth of cut for a single pass is 3 mm.

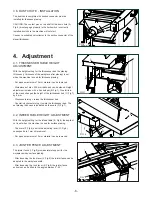

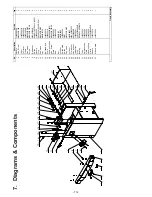

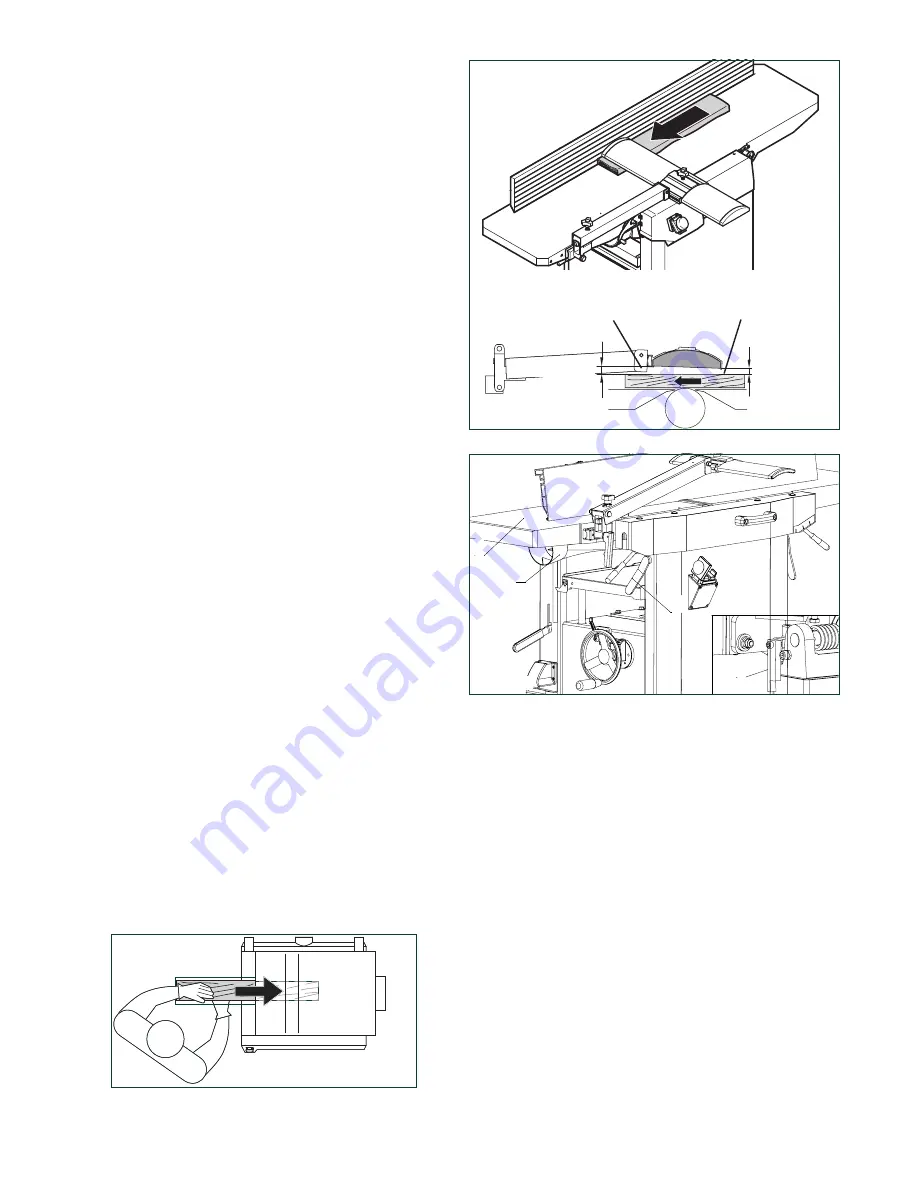

1. Turn clamping lever (B, Fig.15) outward and swing the outfeed

table (C, Fig.15) together with the fence to the left. Make sure

the outfeed table stopper (D, Fig.15) is engaged (When close the

outfeed table, please don't forget the release the stopper first).

2. Turn the dust chute (E, Fig.15) with installed suction connector

to the machine .

3. Assume proper operating position:

- to feed the workpiece into the machine, position yourself offset

to one side of the feed opening.

E

C

B

D

FIG.15

- to remove the workpiece from the machine, position yourself

offset to one side of the outfeed opening.

-10-