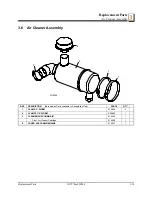

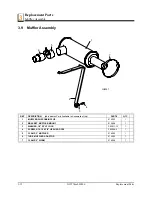

Replacement Parts

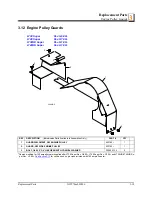

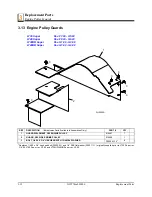

Engine Pulley Guards

Replacement Parts

G3597doc080906

3-18

3

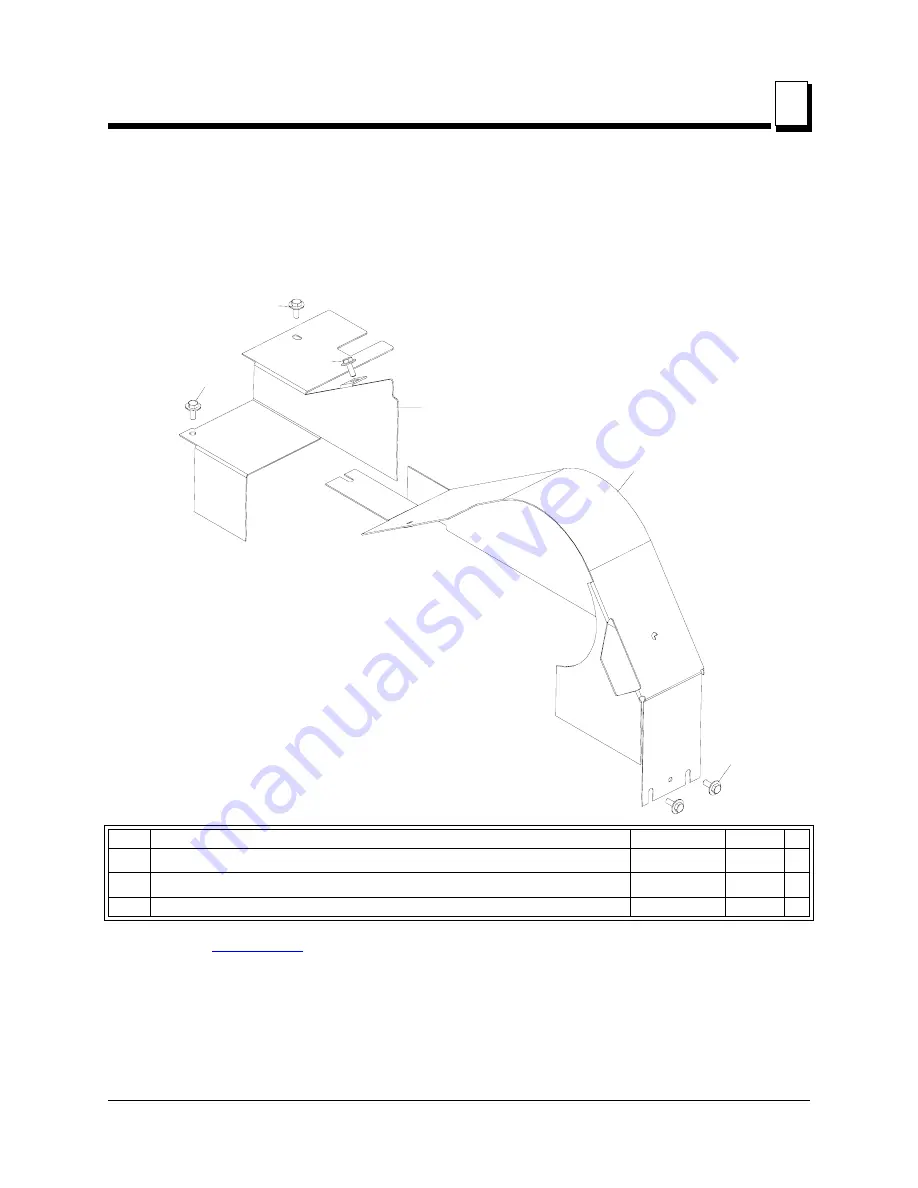

3.12 Engine Pulley Guards

LT30 Super

Rev. G6.00+

LT40 Super

Rev. G7.00+

LT30HD Super

Rev. H1.00+

LT40HD Super

Rev. H1.00+

REF

DESCRIPTION

(

Indicates Parts Available In Assemblies Only)

PART #

QTY.

1

GUARD WELDMENT, G35 ENGINE PULLEY

023792

1

1

Guards modified for 140 amp alternator supplied after LT30 Super Rev. G6.00+, LT40 Super Rev. G7.00+ and LT30HD/LT40HD Su-

per Rev. H1.00+.

for covers used on previous revisions with 105 amp alternator.

1

2

GUARD, G35 SIDE ENGINE PULLEY

023793

1

3

BOLT, 1/4-20 X 3/4” HEX HEAD WITH CONICAL WASHER

F05005-134

5

1

2

3

3

3

3

3H0674-2