Maintenance

RPM Adjustments

2

2-8

doc110909

Maintenance

2.7

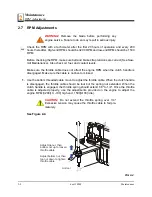

RPM Adjustments

WARNING!

Remove the blade before performing any

engine service. Failure to do so may result in serious injury.

Check the RPM with a tachometer after the first 20 hours of operation and every 200

hours thereafter. High-end RPM should be 3200 RPM and low-end RPM should be 1500

RPM.

Before checking the RPM, make sure belt and brake strap tensions are correct (See Saw-

mill Maintenance). Also check oil, fuel, and coolant levels.

Make sure the throttle cable does not affect the engine RPM when the clutch handle is

disengaged. Make sure the cable is not bent or kinked.

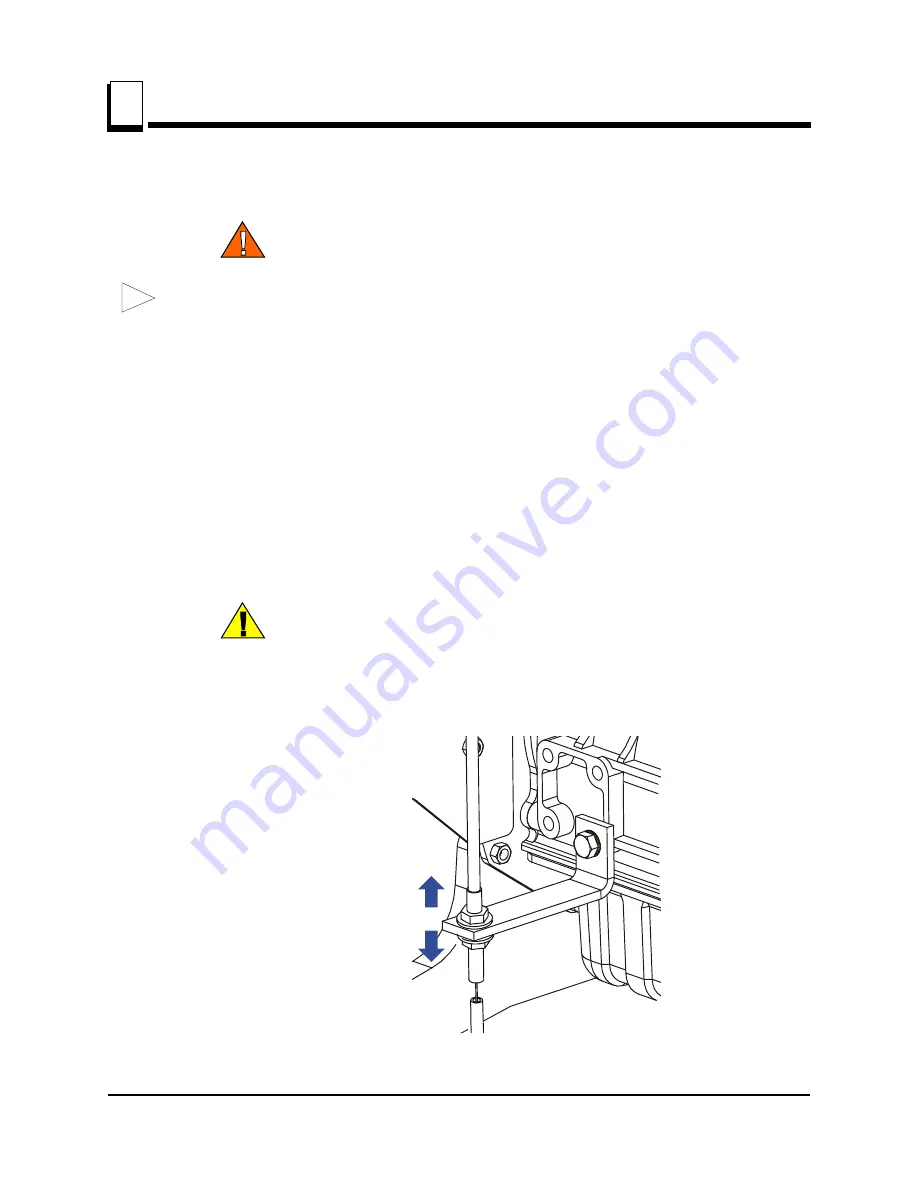

1.

Use the bottom threaded cable mount to adjust the throttle cable. When the clutch handle

is disengaged, the throttle cable should be taut but the spring not extended. When the

clutch handle is engaged, the throttle spring should extend 1/8" to 1/4". Once the throttle

cable is adjusted properly, use the adjustments provided on the engine to adjust the

engine RPM (3200[+0, -100] high-end, 1500[±100] idle).

CAUTION!

Do not extend the throttle spring over 1/4".

Excessive tension may cause the throttle cable to fail pre-

maturely.

See Figure 2-4.

FIG. 2-4

200

Adjust top nut, then

bottom nut up to loosen

throttle cable

Adjust bottom nut, then

top nut down to tighten

throttle cable

3H0748-1