MAINTENANCE

Blade Guides

MAINTENANCE

HDSdoc021716

3-3

3

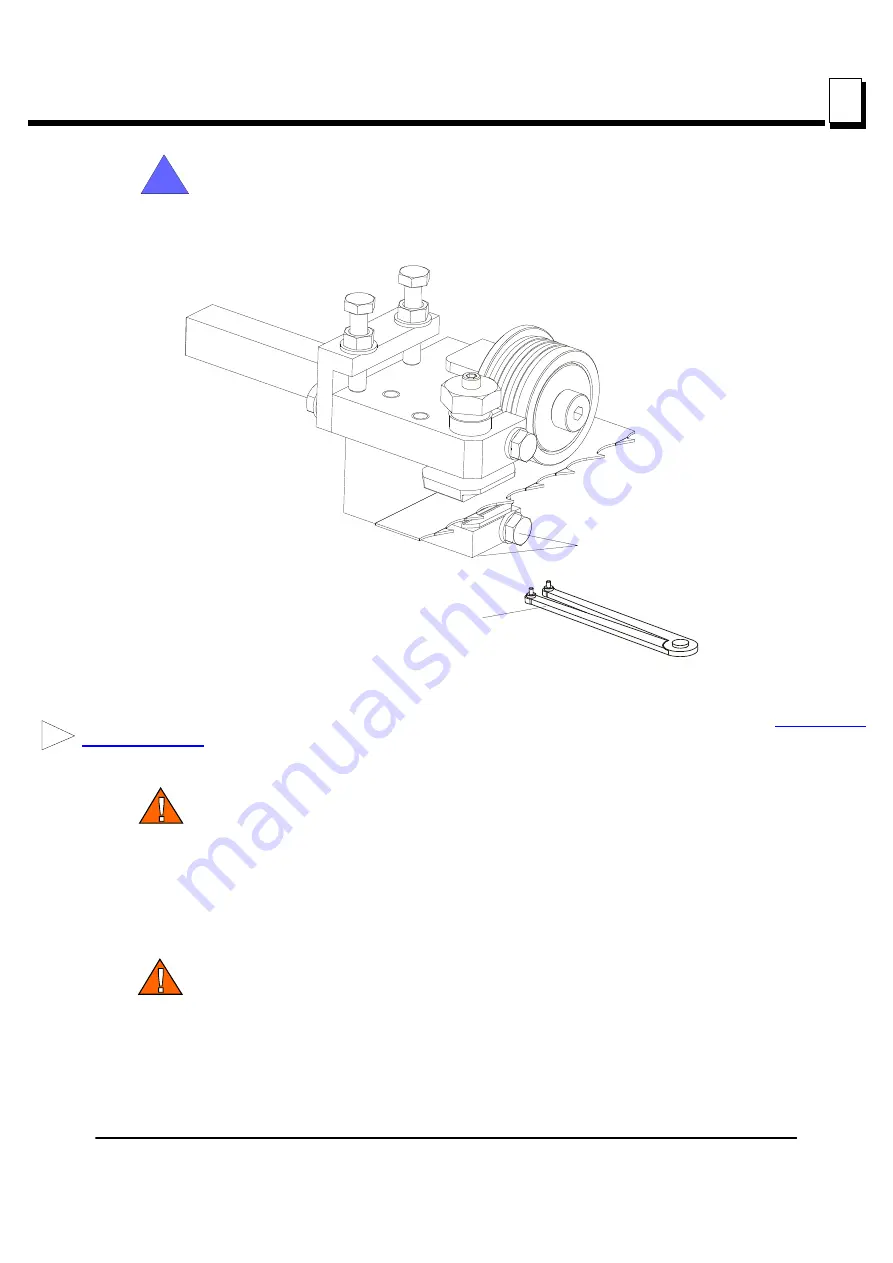

IMPORTANT!

The disks should be parallel to the blade. Check the space

between the disks and the blade at each side of the disks to insure it is

parallel. Use the appropriate adjustment bolt to tilt the disks mounting plate so

the insert is parallel to the blade.

Inspect the blade guide assemblies for proper alignment every time you change the blade.

for blade guide adjustment instructions..

WARNING!

Blade guide alignment is essential for optimal cutting

performance, blade life and safety. Failure to check and maintain proper blade

guide alignment will result in stress cracks forming in the blade. These cracks

will lead to premature blade breakage. If the blade breaks during operation

and the blade has multiple stress cracks, the blade could shatter into several

pieces and escape from the protective guards of the sawmill. Small blade

pieces projected into the area around the sawmill creates a safety hazard for

the operator and any bystanders surrounding the mill.

WARNING!

DO NOT use blades with stress cracks. Blades with stress cracks

can shatter causing bodily injury and/or machine damage.

Preventing sap buildup on the blade is critical when using the high-performance blade guide system. If the

wood you are sawing leaves sap buildup using plain water in the blade lube system, use Wood-Mizer lube

additive (Part No. 033439).

Throat Screw

FIG. 3-1

!

Loosen

mounting

bolt and

clamp bolt

Use bottom disk

adjustment tool to

raise bottom disk