height, weather, log size, wood species and moisture

content. Some experimentation will initially be required

to

fi

nd that “sweet spot” where your stove performs best.

The following will give you a starting point to

find

your

optimum settings.

When

fi

rst loading fuel set the primary air inlet con-

trol (center) at the wide open (Pull out) position for at

least 15–20 minutes (the high burn duct control should

be closed – pulled out – when starting

fires)

. When the

stove is working properly you should be able to observe

secondary combustion

flames

above the fuel pieces in

front of the secondary air tubes at the top of the

fi

rebox.

These secondary

flames

should continue to burn after

the primary air inlet is reset from wide open to the de-

sired operating setting. If the

flames

do not continue to

burn, open the air control to re-establish the secondary

flames

then slowly reset the air control to the desired

setting. Initially it may take several attempts to

figure

your stove out. But once you

find

the operating “sweet

spot” and the correct mix of procedures to get there,

only minor adjustments will be necessary.

The best indicator of a properly operating stove is

to look for smoke coming out of the chimney. You may

see steam emissions that will quickly dissipate. Smoke

will thin but continue to drift without totally disappearing.

If you do detect smoke emissions, open the air control

a little bit, let the stove adjust for 10–15 minutes and

re-check your chimney. Remember – visible smoke

represents lost heat.

NOTICE - INITIAL BURNS TO CURE PAINT

BECAUSE OF THE HIGH OPERATING

TEMPERATURES, THIS STOVE USES

A SPECIAL HIGH-TEMP PAINT WHICH

REQUIRES A SERIES OF BURNS TO

CURE THE PAINT FOR DURABILITY AND

A LIFETIME OF SERVICE.

P r o p e r c u r i n g o f t h e h i g h - t e m p p a i n t

requires a series of three initial burns. The stove

should be allowed to cool off between each burn.

The first two burns should be small fires and low

temperatures (250°F/120°C) for a duration of

20 minutes each. The third fire should be at a

medium-high temperature (500 to 700°F/260 to 370°C)

for twenty minutes. Provide adequate cross ventilation

to clear any smoke or odor caused b

y initial fi

rings.

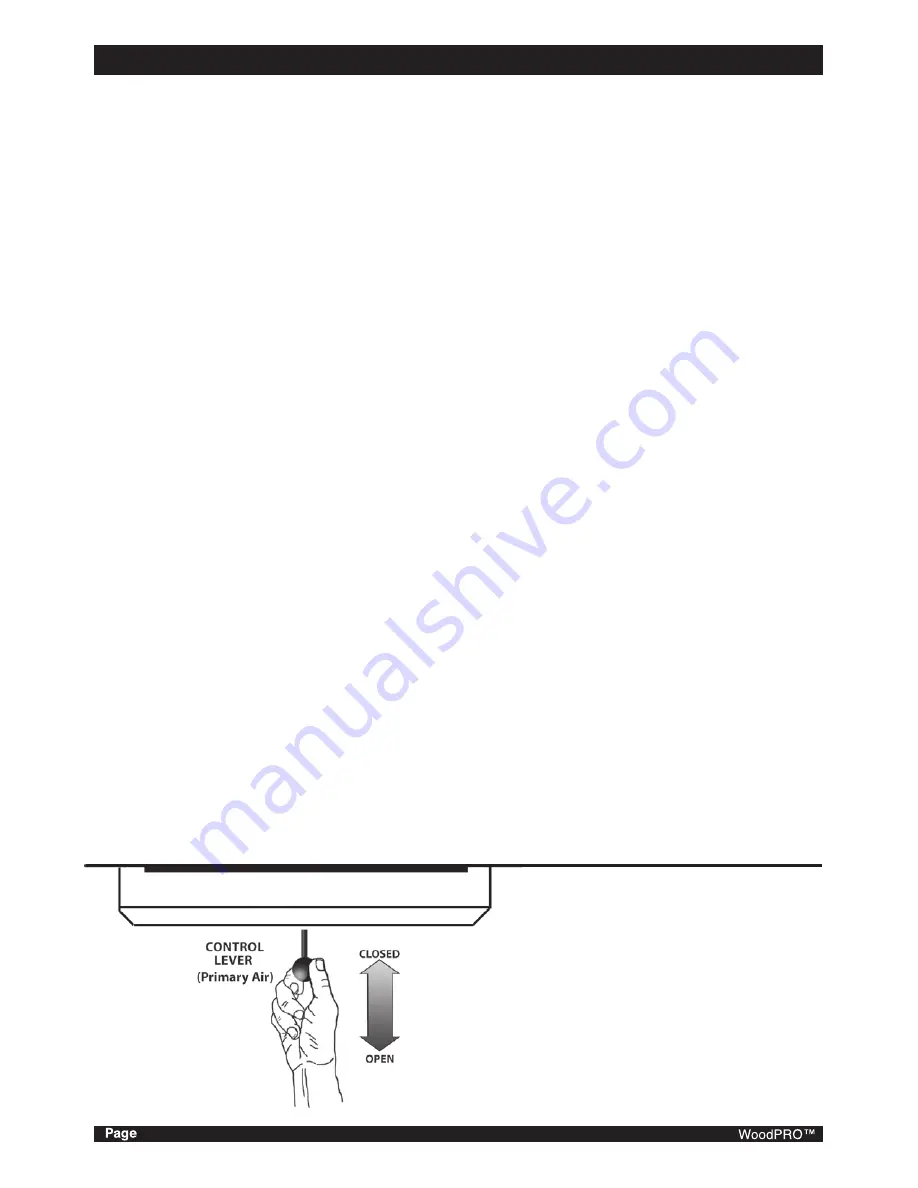

STARTING A FIRE

1. Set

Primary Air Inlet Control Lever

(round ball

control located under the center of the ash lip)

to thefully open position(pull control out towards

you).

NOTE: OPEN/HIGH=OUT; CLOSED/LOW=IN.

2. Open the feed door and place several wads of

cr

ushed paper in the fireb

ox.

3. Cover the paper with a generous amount of kindling

in a teepee fashion and a few small pieces of wood.

4. Ignite the paper and leave the door open slightly.

DO NOT LEAVE STOVE UNATTENDED WITH

DOOR OPEN! Except while tending the

fi

re,

operating the stove with the feed door open or

ash clean out cover removed may cause over

firing

resulting in unsafe operating conditions.

5. Add large pieces of wood as the

fire

progresses

being careful not to overload. (Do not

fill

fireb

ox

beyond

fireb

rick area.) An ideal coal bed of

1˝

–

2˝

(25mm - 50mm) should be established to achieve

optimum performance.

6. This unit is designed to function most effectively

when air is allowed to circulate to all areas of the

fireb

ox. TIP: If ash or coals remain in the stove,

continued on next page

make sure to clear them away from the Lower

Primary Air Or

ifice

(LPAO) and rake a slight

(1˝

–

2˝/25mm-50mm

wide) trough down the center of

the coal bed from front to back prior to loading the

fuel.

OPERATING INSTRUCTIONS

...continued

ASH LIP

18

Summary of Contents for WS-TS-1500

Page 6: ...6 Minimum Clearances for installation according to UL 1482 US ULC S627 CAN A ...

Page 7: ...7 Top A A Alcove ...

Page 8: ...philips BLOWER ATTACHMENT 8 4 places A GASKET ...

Page 9: ...9 WS TS 2500 23 8 6 ...

Page 10: ...10 6 ...

Page 20: ...20 ...

Page 21: ...21 ...

Page 23: ...23 BAFFLE REMOVAL ...

Page 24: ...24 BAFFLE REMOVAL ...

Page 25: ...SERVICE PARTS 25 ...

Page 26: ...SERVICE PARTS 26 ...

Page 27: ...SERVICE PARTS 27 ...

Page 28: ...SERVICE PARTS 28 ...

Page 29: ...SERVICE PARTS 29 ...

Page 30: ...SERVICE PARTS WS TS 2500 30 ...

Page 33: ...DATE OF SERVICE PERFORMED BY DESCRIPTION CHIMNEY STOVE MAINTENANCE LOG 33 ...

Page 35: ...Warranty 35 ...

Page 36: ...36 www woodprostoves com 2 ...