22

WOODS

PRE-OPERATION CHECK LIST

(OPERATOR’S RESPONSIBILITY)

___ Review and follow all safety rules and safety

decal instructions.

___ Check that all safety decals are installed and in

good condition. Replace if damaged.

___ Check to make sure all shields and guards

are properly installed and in good condition.

Be sure that either the discharge shield or

complete vacuum attachment is installed.

___ Check that all hardware is properly installed.

and secured.

___ Check that equipment is properly and securely

attached to power unit.

___ Check to be sure engine is free of dirt and

debris. Pay particular attention to the cooling

fins, governor parts and muffler. Clean air

intake screen. Check air cleaner; service if

necessary.

___ Never allow riders.

___ Inspect area and remove stones, branches or

other hard objects that might be thrown,

causing injury or damage.

___ Clean area around oil fill dipstick. Remove

dipstick and check to be sure oil is in operating

range (between marks on dipstick). Add oil if

necessary but

Do Not Overfill

. Install dipstick

assembly firmly until cap bottoms out on tube.

Dipstick assembly must always be secured into

fill tube when engine is running.

___ Check all lubrication points and grease as

instructed in manual.

___ Check hydrostatic fluid level. Check to be sure

cooling fins on hydrostat are clean.

___ Perform a functional check of the safety

interlock system each time you operate the

unit.

PRE-OPERATION CHECK LIST

Summary of Contents for 872311G

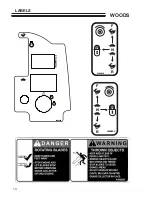

Page 15: ...15 WOODS LABELS...

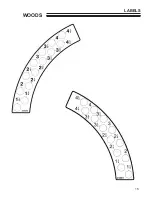

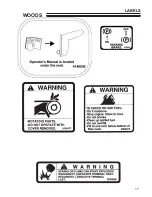

Page 17: ...17 WOODS LABELS...

Page 40: ......

Page 41: ...41 WOODS PARTS SECTION PARTS SECTION...

Page 44: ...44 WOODS 15 24 17 45 45 42 FIGURE 2 TRANSAXLE ASSY...

Page 52: ...52 WOODS FIGURE 6 CASTER ASSEMBLY...

Page 56: ...56 WOODS FIGURE 8 STEERING...

Page 58: ...58 WOODS FIGURE 9 PARKING BRAKE...

Page 66: ...66 WOODS FIGURE 13 BELTS CUTTERDECK...

Page 70: ...70 WOODS FIGURE 16 ACCESSORIES SUSPENSION SEAT 4 3 1 1 2 6 7 5...