ITM PART NO.

DESCRIPTION

QTY

45

ITM PART NO.

DESCRIPTION

QTY

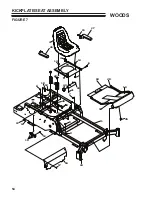

WOODS

FIGURE 2

TRANSAXLE ASSY

1

4164049

S-FRAME W/LABELS

1

2

4162973

SHAFT-PULLARM MOUNT

1

3

4163957.7

WLDMT-PULL ARM

2

4 4163819

ARM-CONTROL

2

5 4163493

AXLE-LH

1

(INCLUDES ITEMS 4, 25, 26, 27, 32)

6 64163-29 WASHER

2

7

64123-68

BOLT-HEX 5/16-18X1

2

8

64025-02

NUT-HEX 5/16-18

2

9

64270-01

BOLT-MET, HEX M10-1.5x30

1

10 64123-54

BOLT, 5/16-18X3/4 HEX

2

11 64163-55

WASHER .328X.75X14 GA

6

12 4164128

SPRING-TENSION

1

13 64123-67

BLT-HEX 3/8-16 X 2

1

14 4128001

END CAP-24 X 7

1

15 64268-02

NUT-FL NYLON LOCK 5/16-18 10

16 2228016

PULLEY-IDLER PUMP

1

17 64163-31

WASHER, 25/64X1X12

8

18 64123-55

BLT-HEX 5/16-18X3

4

19 64229-03

LOCKNUT-NYLON 3/8-16

1

20 4163494

AXLE-RH

1

(INCLUDES ITEMS 4, 25, 26, 27, 32)

21 4143636

BELT-TRANSAXLE

1

22 4163276

ROD-BATTERY CLAMP

2

23 108055

BATTERY

1

24 64123-88

BLT-HEX 3/8-16X2-3/4

4

25* 4142045-06 FILTER-TRANSAXLE

2

26* 4163819

SPRING-CONTROL ARM

2

27 4163820

ARM-BRAKE

2

4164862 CLIP-RETAINING

2

(USE WITH BRAKE ARM)

28 64123-168

BLT-HEX 5/8-11X2-1/2

2

29 64163-93

WSHR-.635 X 1.12 X.062

4

30 85010N

ZERK, 1/4-28

4

31 64229-06

LOCKNUT, NYLON 5/8-11

2

32 4164048

KIT-FAN/PULLEY TRANSAXLE 2

33 4142752

TIRE ASSY 20 X 8 - 10 4 PLY

2

4142752-01 TIRE-20X8-10 4 PLY MULTI TRAC

4132433-02 RIM 10X7

(USED ON 42" DECKS ONLY)

4155841

TIRE-ASSY 20 X 10-10

2

4132433-01 TIRE 20X10-10 TURFMASTER

4155841-01 WHEEL 10X7 W/ STEM

(USED ON 52" DECKS ONLY)

34 64187-03

WHEEL NUT 1/2-20

8

35 4133302

S-ASSY-IDLER ARM PUMP

1

(INCLUDES ITEMS 36-38)

36 4128004

BEARING-BALL 10X26X8

2

37 64144-40

SNAP RING-26MM INTERNAL 1

38 4128000

SEAL-16X26X7

1

39 64163-61

WASHER

2

40 4163299.7 TRAY-BATTERY

1

41 64197-022

BLT-TDFM 3/8-16 X 3/4

3

42 4163264-01 ADAPTER-90 #6 MAORB/#6 FORB 1

43 4163307

ASSY-EXPANSION TANK

2

44 4142808-01 CAP-HYDROTANK

2

45 64268-03

NUT-FL NYLON LOCK 3/8-16

4

46* 4164227

CHARGE PUMP COVER KIT

1

47* 4163771-01 GUARD-FILTER LH

1

48* 4163772-01 GUARD-FILTER RH

1

* NOT ILLUSTRATED

Summary of Contents for 872311G

Page 15: ...15 WOODS LABELS...

Page 17: ...17 WOODS LABELS...

Page 40: ......

Page 41: ...41 WOODS PARTS SECTION PARTS SECTION...

Page 44: ...44 WOODS 15 24 17 45 45 42 FIGURE 2 TRANSAXLE ASSY...

Page 52: ...52 WOODS FIGURE 6 CASTER ASSEMBLY...

Page 56: ...56 WOODS FIGURE 8 STEERING...

Page 58: ...58 WOODS FIGURE 9 PARKING BRAKE...

Page 66: ...66 WOODS FIGURE 13 BELTS CUTTERDECK...

Page 70: ...70 WOODS FIGURE 16 ACCESSORIES SUSPENSION SEAT 4 3 1 1 2 6 7 5...