Assembly

23

MAN1257 (3/23/2018)

ASSEMBLY INSTRUCTIONS

DEALER SET-UP INSTRUCTIONS

Assembly of this cutter is the responsibility of the WOODS dealer. It should be

delivered to the owner completely assembled, lubricated and adjusted for nor

-

mal cutting conditions.

The cutter is shipped partially assembled. Assembly will be easier if compo

-

nents are aligned and loosely assembled before tightening hardware. Recom

-

mended torque values for hardware are located on page 48.

Select a suitable working area. A smooth hard surface, such as concrete, will

make assembly much quicker. Open parts boxes and lay out parts and hard

-

ware to make location easy. Refer to illustrations, accompanying text, parts lists

and exploded view drawings.

Complete the check list on page 23 when assembly is complete and cutter is

delivered to the customer.

Before working underneath, carefully read Operator’s Manual

instructions, disconnect driveline, raise mower, securely block up all cor

-

ners with jackstands, and check stability. Secure blocking prevents

equipment from dropping due to hydraulic leak down, hydraulic system

failures, or mechanical component failures.

Do not disconnect hydraulic lines until machine is securely blocked

or placed in lowest position and system pressure is released by operat

-

ing valve levers.

Always wear relatively tight and belted clothing to avoid entangle

-

ment in moving parts. Wear sturdy, rough-soled work shoes and protec

-

tive equipment for eyes, hair, hands, hearing, and head; and respirator or

filter mask where appropriate.

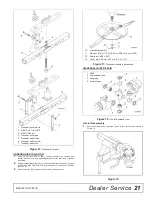

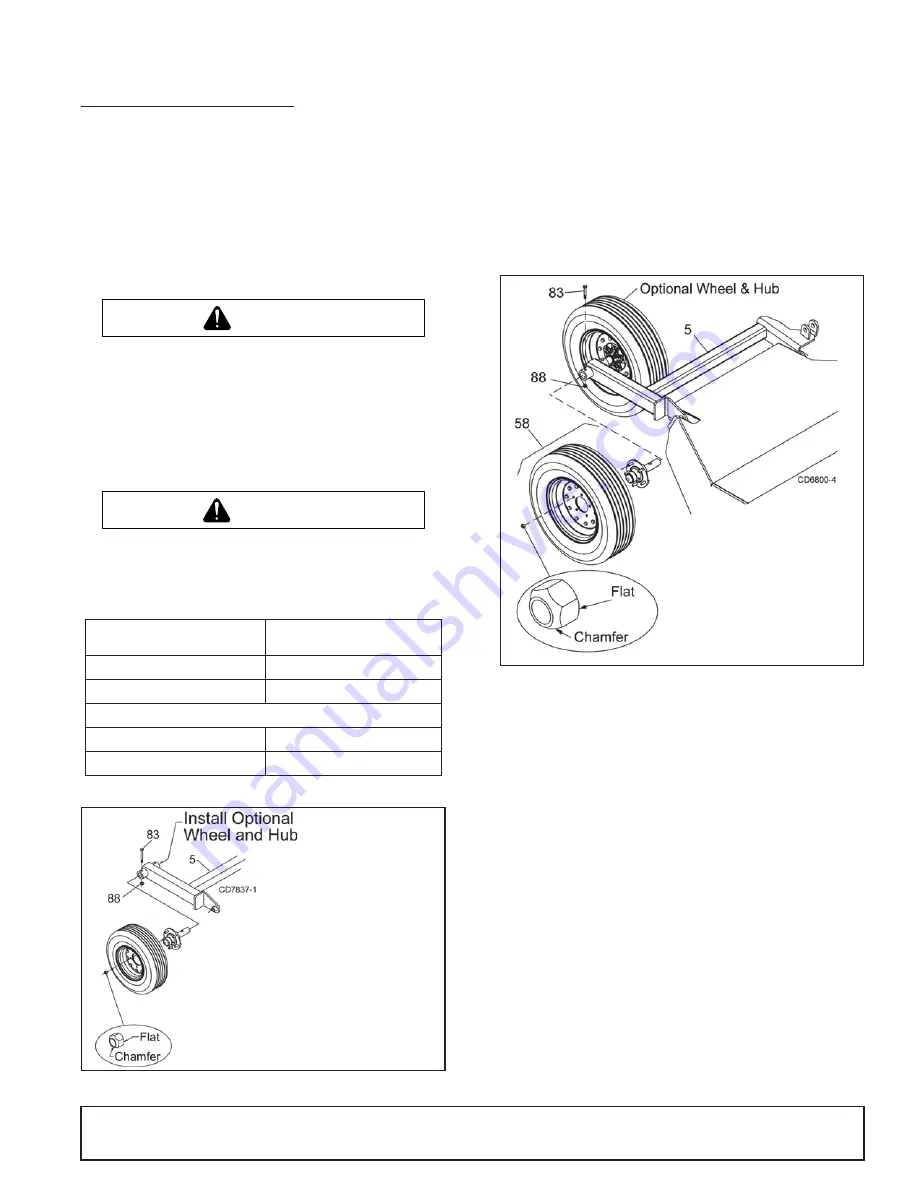

Install Wheel

Figure 24

Center Section Wheel and Hub Installation

Install Wing Wheel

(Figure 25)

1.

Insert wheel hub into wing wheel yoke arms (5) and align holes.

2.

Secure into position using cap screw (83) and flanged lock nut (88).

3.

Attach wheel to hub using five lug nuts. Install the chamfered side of the

lug nut toward the inside for steel rim for pneumatic tires and rims.

Tighten to 115 Nm (85 lbs-ft). Check that tire air pressure is a maximum

of .27 MPa (40 psi).

NOTE:

Install the flat side of the nut toward the inside for solid

tires and aircraft tires (shown).

4.

Install optional dual wheel and hub to inside of wheel yoke arm.

Figure 25

.

Wing Wheel - Right

Winch Kit Installation (Optional)

Refer to page 46 for Installation and Operation instructions.

Tandem Axle Arm Installation (Optional)

Refer to page 47 for Installation and Operation instructions.

Shredding Kit Installation (Optional)

Refer to page 48 for Installation and Operation instructions.

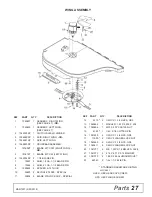

Small Aircraft Tires

Attitude Rod Length

Beyond Nuts (34)

Tongue at 279 mm

88.9 mm

Tongue at 457 mm

44.5 mm

Large Aircraft Tires

Tongue at 279 mm

114 mm

Tongue at 457 mm

63.5 mm

WARNING

CAUTION

CAUTION

1. Center Wheel Yoke Arm

83. 1/2" NC x 3" HHCS GR5

88. 1/2" NC Flange Lock Nut

5. Wing wheel yoke arm, right

58. Wheel and hub

83. 1/2 NC x 3 HHCS GR5

88. 1/2 NC Flanged lock nut

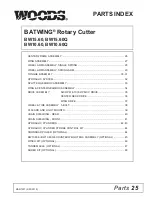

Summary of Contents for Batwing BW10.60E

Page 9: ...Declaration of Conformity9 MAN1257 3 23 2018...

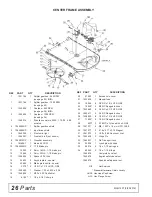

Page 30: ...30 Parts MAN1257 3 23 2018 TONGUE ASSEMBLY...

Page 54: ...BATWING FAUCHEUSE ROTATIVE MAN1257 R v 23 03 2018 BW15 60E BW15 60QE BW10 60E BW10 60QE...

Page 62: ...D claration de conformit 9 MAN1257 23 03 2018...

Page 76: ...BATWING TRINCIATRICE ROTANTE MAN1257 Rev 23 03 2018 BW15 60E BW15 60QE BW10 60E BW10 60QE...

Page 84: ...Dichiarazione di conformit 9 MAN1257 23 03 2018...

Page 98: ...BATWING ROLLSCHNEIDER MAN1257 Rev 23 03 2018 BW15 60E BW15 60QE BW10 60E BW10 60QE...

Page 106: ...Konformit tserkl rung 9 MAN1257 23 03 2018...

Page 120: ...BATWING DESBROZADORA GIRATORIA MAN1257 Rev 23 3 2018 BW15 60E BW15 60QE BW10 60E BW10 60QE...

Page 128: ...Declaraci n de conformidad 9 MAN1246 14 12 2017...