20

Owner Service

MAN1078 (2/6/2014)

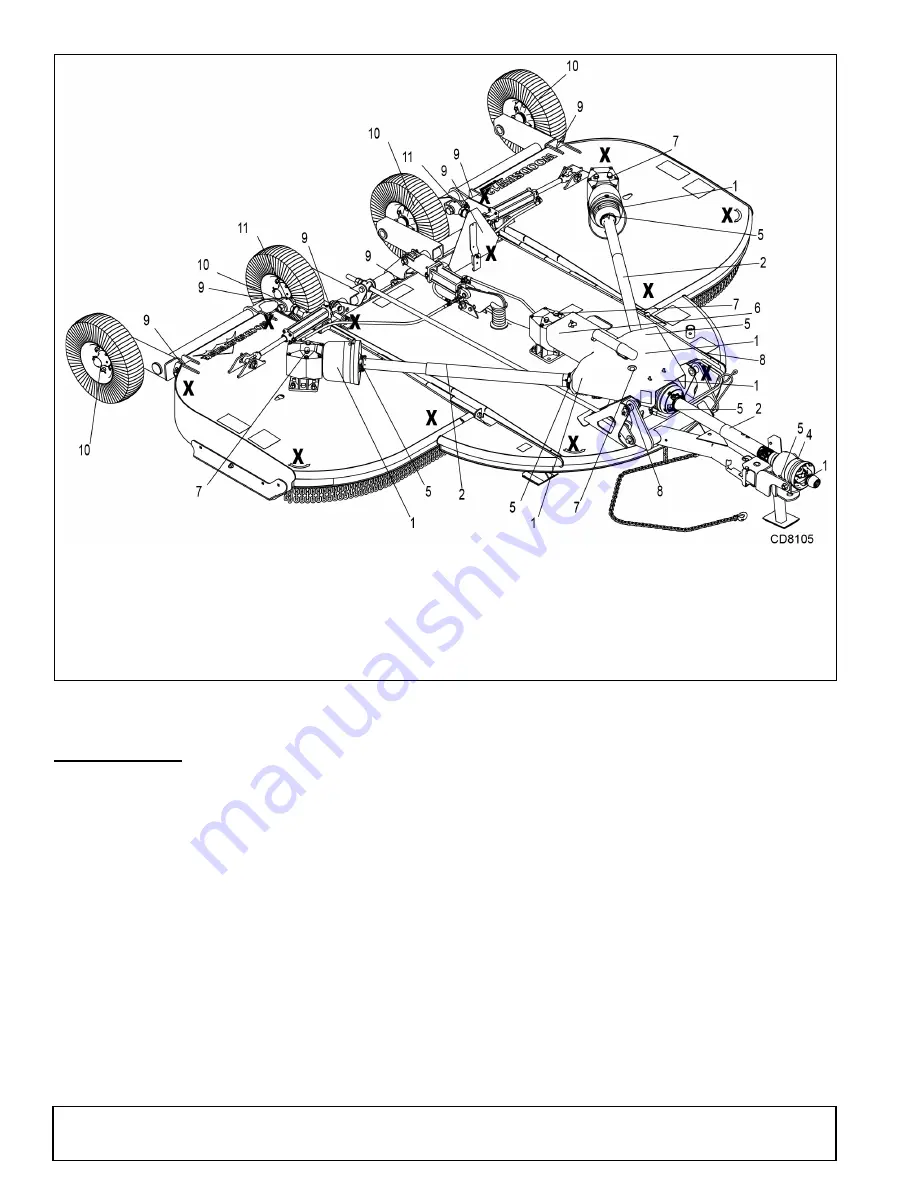

Figure 6

. Jackstand Placement and Lubrication Points

LUBRICATION

Do not let excess grease collect on or around parts,

particularly when operating in sandy areas.

See Figure 6 for lubrication points and frequency for

lubrication based on normal operating conditions.

Severe or unusual conditions may require more fre-

quent lubrication.

Use a lithium grease of #2 consistency with a MOLY

(molybdenum disulfide) additive for all locations unless

otherwise noted. Be sure to clean fittings thoroughly

before attaching grease gun. One good pump of most

guns is sufficient when the lubrication schedule is fol-

lowed.

Gearbox Lubrication

For gearbox, use a high quality gear oil with a viscosity

index of 80W or 90W and an API service rating of GL–

4 or –5 in gearboxes. Fill gearbox until oil runs out the

side plug on gearbox. Check gearbox daily for evi-

dence of leakage, and contact your dealer if leakage

occurs. Use sealant on vent plug threads during instal-

lation. Check vent plug periodically and clean if it does

not relieve pressure.

Driveline Lubrication

1.

Lubricate the driveline slip joint every eight

operating hours. Failure to maintain proper

lubrication could result in damage to U-joints,

gearbox, and driveline.

2.

Lower cutter to ground, disconnect driveline from

tractor PTO shaft, and slide halves apart but do not

disconnect from each other.

3.

Apply a bead of grease completely around male

half where it meets female half. Slide drive halves

over each other several times to distribute grease.

1. Driveline U-joint

10 Hours

2. Telescoping shaft

10 Hours

4. CV body assembly

10 Hours

(10 pumps minimum)

5. Driveline shield

10 Hours

6. Splined yoke

10 Hours

7. Gearbox

Daily

8. Tongue pivot

40 Hours

9. Wheel yoke pivot

40 Hours

10. Tailwheel spindle

20 Hours

11. Turnbuckle

40 Hours