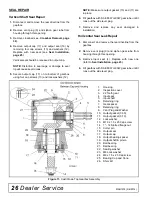

Dealer Service

29

MAN1078 (2/6/2014)

14.

Slide bearings (16 & 13) and shims (12) over each

end of the center shaft (14). Secure bearings into

position using snap rings (10).

15.

Check end play of shaft by moving it in and out. If

end play is more than 0.012", insert another shim

(12) between snap ring and bearing. Repeat

process until end play is less than 0.012".

16.

Check rotational torque. Torque should be less

than 2.2 lbs-inch gear.

17.

Check gear backlash, backlash should be between

0.006" and 0.016". You should not have to adjust

for backlash.

18.

Place seal (11) over shaft and press into housing

using a tube of the same diameter. Seal should be

flush with housing when properly installed. Repeat

process for opposite end shaft.

Check Gearbox

1.

Place top cover (21) on housing and secure into

position using six cap screws (20).

2.

Check gearbox for leaks by: plugging all holes

except one, applying 4 psi of compressed air, and

immersing gearbox in water. Verify gearbox does

not leak.

NOTE:

Excessive air pressure will damage seals.

3.

Remove gearbox from water and dry off.

4.

Remove upper plug (3) on right side of housing.

Add SAE 80W or 90W EP oil until it runs out side

level hole. Replace plug.

5.

Install breather (18) in top cover.

Reinstallation on Cutter

NOTE:

Gearbox is heavy: do not attempt to move it

without mechanical assistance.

1.

Place gearbox on cutter and secure into position

using four cap screws and lock washers.

2.

Torque hardware to 300 lbs-ft.

3.

Attach all drivelines to gearbox.

4.

Install all shields.

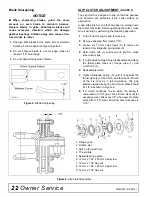

Figure 14

. Splitter Gearbox Assembly

1. Shaft 1-3/4, 20 spline, wing

2. Oil seal

3. 3/8 plug

4. Snap ring

5. Bearing

6. Pinion gear

7. Bearing

8. Shim

9. Housing

10. Snap ring

11. Oil seal

12. Shim

13. Bearing

14. Shaft 1-3/4, 20 spline, center

15. Snap ring

16. Bearing

17. Gear

18. 1/2 Breather

19. 5/16 Lock washer

20. M8 x 30 Cap screw 8.8

21. Cover

22. Snap ring