Dealer Service

25

MAN1289 (10/18/2019)

adjust output bearings to a rolling torque of 9 to 12

In-lbs.

NOTE:

Be sure output gaskets (10 and 11) are in

place. Apply grease to output seal (16) lip for easy

installation.

8.

Place ball bearing (21) at back of housing and

press in socket using a round tube of the correct

diameter and a hand press until fully seated.

9.

Insert input shaft (5) part way through housing and

slide gear (3) and retaining ring (6) over input shaft

(5). Keep gear (3) and retaining ring (6) loose.

10.

Insert input shaft (5) into roller bearing (21) until

seated against each other.

11.

Slide gear (3) forward and attach retaining ring (6)

in groove closest to front of input shaft (5). Slide

gear (3) back against retaining ring (6).

12.

Check that the gear backlash is between 0.006"

and 0.016". You should not have to adjust the

backlash.

13.

Slide gear spacer (7) and ball bearing (20) on input

shaft (5) and secure with retaining rings (6) and (8).

14.

Slide input seal (4) onto input shaft (5) and press

into housing flush with front using a tube of correct

diameter. Be careful not to damage seal lip.

15.

Check gearbox housing for leaks by plugging all

holes except one. Apply 4 psi compressed air and

immerse the gearbox in water to verify that there

are no leaks.

Remove gearbox from water and dry off with com-

pressed air. Add SAE 80W or 90W EP oil until it runs

out of side level hole. Tighten all plugs.

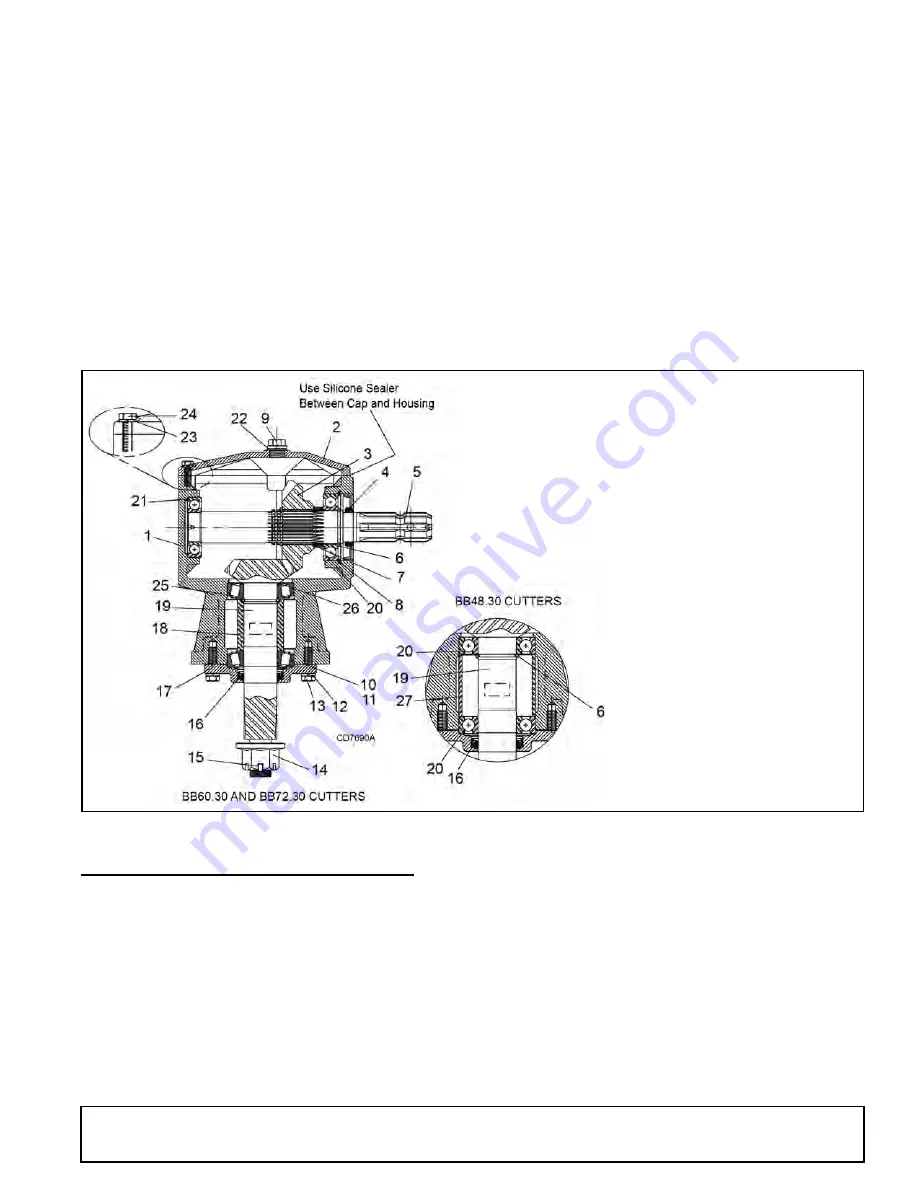

Figure 17

. BB48.30, BB60.30, BB72.30 Gearbox Assembly

SPINDLE GEARBOX REPAIR - BB84.40

(Figure 18)

NOTE:

Replacing gears, shafts, bearings, and seals

may not be cost effective. Purchasing a complete gear-

box may be more economical.

Remove Gearbox from Cutter

1.

Disconnect and remove the driveline from the

gearbox.

2.

Remove vent plug (3) and siphon gear lube from

housing through this opening.

3.

Remove cotter pin, washer, and nut from vertical

shaft and remove crossbar. Hydraulic jack will not

operate if tipped more than 90-degrees. Use care

to prevent bending crossbar during removal. See

page 27.

4.

Remove the four bolts that attach gearbox to cutter

and remove gearbox. Gearbox is heavy; do not

attempt to move without mechanical assistance.

Disassemble Gearbox

1.

Remove 3/8" plug from side of gearbox and pour

out gear oil.

2.

Remove oil cap (24) (to be replaced).

1.

Housing

2.

Inspection cover

3.

22 Tooth gear

4.

Input seal

5.

Input shaft

6.

Retaining ring

7.

Gear spacer

8.

Retaining ring

9.

Vent Plug and Washer

10.

Output gasket (0.30)

11.

Output gasket (0.13)

12.

Lock washer

13.

M10 x 1.5 x 25 Cap screw

14.

1" - 14 Slotted flange nut

15.

Cotter pin

16.

Output seal

17.

Output cap

18.

Output bearing spacer

19.

Output shaft & pinion

20.

Ball bearing

21.

Ball bearing

22.

Sealing washer

23.

M8 Lock washer

24.

M8 x 1.5 x 25 Cap screw

25.

Bearing Cup and Cone

26.

Shim Kit

27.

Output Bearing Spacer