Owner Service

21

MAN0632 (5/15/2007)

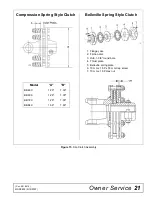

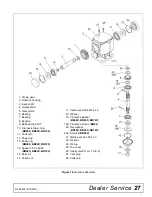

Figure 15

. Slip Clutch Assembly

1. Flange yoke

2. Friction disc

3. Hub, 1-3/8" round bore

4. Thrust plate

5. Belleville spring plate

6. 10 mm x 1.5P x 55 mm Cap screw

7. 10 mm x 1.5P Hex nut

Compression Spring Style Clutch

Belleville Spring Style Clutch

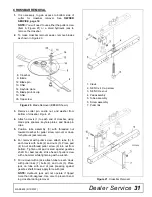

Model

"A"

"B"

BB48X

1.26"

7.09"

BB60X

1.26"

7.09"

BB72X

1.26"

7.09"

BB84X

1.36"

7.68"

(Rev. 5/21/2018)