Assembly

39

MAN0632 (5/15/2007)

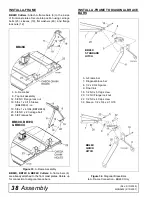

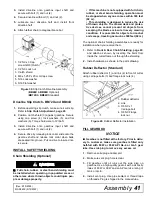

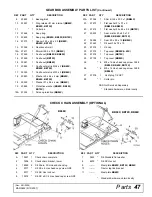

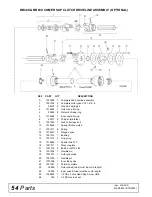

INSTALL TAILWHEEL

1.

Attach tailwheel bracket (6) to cutter at the

tailwheel pivot holes (5B) using cap screw (13) and

flange lock nut (14) previously removed.

NOTE:

Make sure grease fitting on tube is on top

when installing tailwheel.

2.

Select desired height adjustment holes (10), and

secure tailwheel bracket with cap screws (13) and

flange lock nuts (14). Cutting height adjustment will

be necessary when cutter is fully assembled. See

page 16.

3.

Raise rear of cutter and insert tailwheel assembly

(9) into tailwheel bracket (6). Secure with washer

(37) and spiral pin (28).

4.

Place diagonal brace bars (4) on the inside of

frame rails and attach to diagonal brace mounting

holes (5A). Secure using cap screws (13) and

flange lock nuts (14).

Figure 35

. Tailwheel Installation

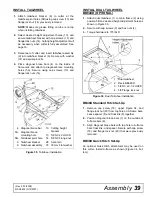

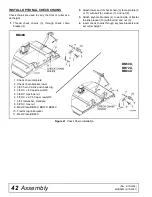

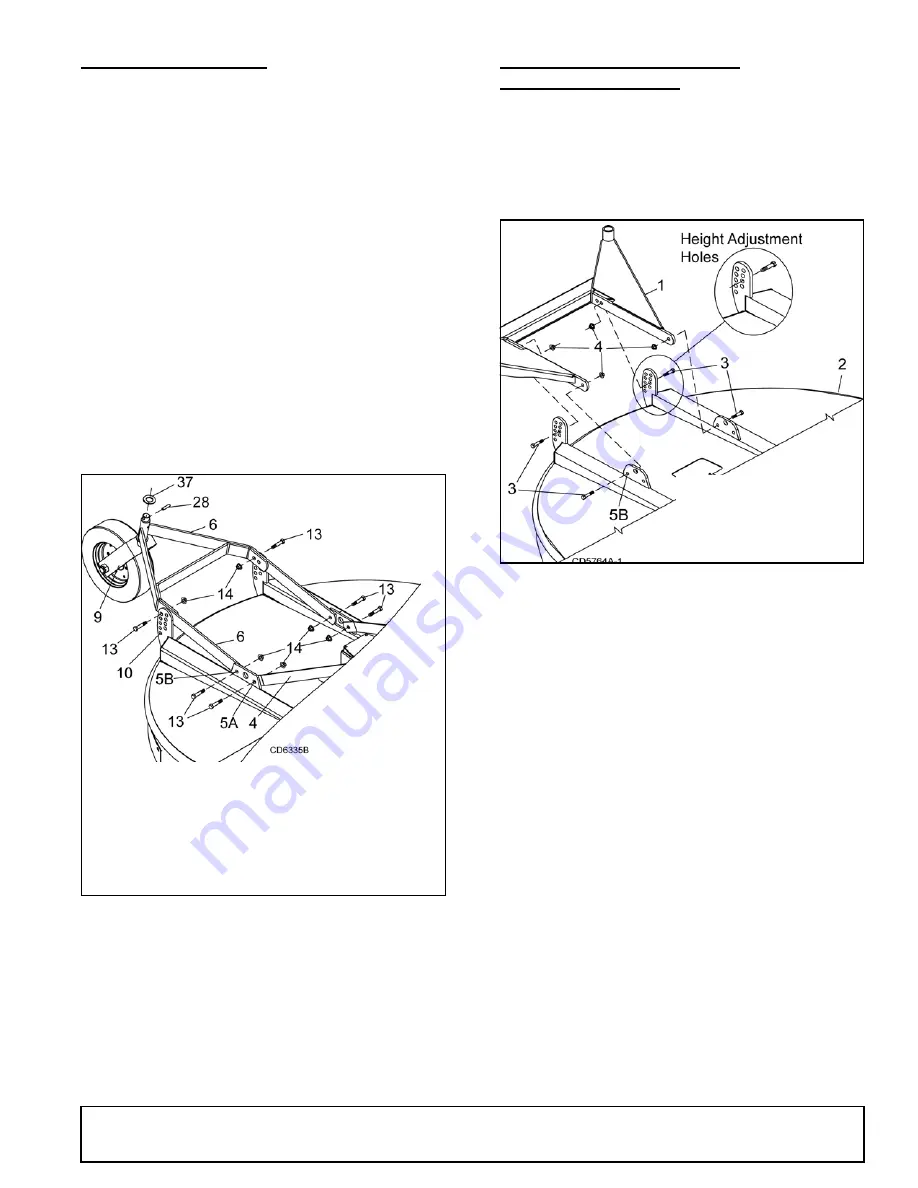

INSTALL DUAL TAILWHEEL

BB84XD (OPTIONAL)

1.

Attach dual tailwheel (1) to main frame (2) using

position 5B and desired height adjustment holes as

shown in Figure 36.

2.

Secure with cap screws (3) and hex nuts (4).

3.

Torque hardware to 175 lbs-ft.

Figure 36

. Dual Tailwheel Installation

BB48X Standard Hitch Set-Up

1.

Remove cap screw (18), upper Figure 34, and

flange lock nut (20) from top hole on A-frame bars.

Leave spacer (8) and float link (9) together.

2.

Position diagonal brace bars (7) on the outside of

A-frame bars (6).

3.

Align diagonal brace bars with top hole in A-frame

bars, float link, and spacer. Secure with cap screw

(18) and flange lock nut (20) that were previously

removed.

BB48X Quick Hitch Set-Up

An optional Quick Hitch attachment may be used on

this cutter. Install A-frame as shown (Figure 34, bot

-

tom).

4. Diagonal brace bar

5A. Diagonal brace

mounting hole

5B. Tailwheel pivot hole

6. Tailwheel bracket

9. Tailwheel assembly

10. Cutting height

bracket

13. 5/8 NC x 2 HHCS

14. 5/8 NC Flange nut

28. Spirol pin

37. 33 mm Flat washer

1. Dual tailwheel

2. Deck, BB84XD

3. 5/8 NC x 2-1/2 HHCS

4. 5/8 Flange lock nut

(Rev. 5/10/2009)