Operation

11

MAN0646 (7/6/2007)

OPERATION

The operator is responsible for the safe operation of

this Mow’n Machine. The operator must be properly

trained. Operators should be familiar with the power

unit, all attachments that will be used, and all safety

practices before starting operation. Read the safety

rules and safety decals on page 5 through page 10.

Operators must be instructed in and be capable

of the safe operation of the equipment, its attach-

ments, and all controls. Do not allow anyone to

operate this equipment without proper instructions.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

Inspect and clear area of stones, branches, or

other hard objects that might be thrown, causing

injury or damage.

Do not operate power unit with attachment

removed. Attachment is required for power unit

stability.

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

Handle fuel carefully; it is highly flammable.

Always use an approved container. Never remove

fuel cap or add fuel while engine is running. Allow

engine to cool before refueling. Wipe up all spilled

fuel before starting engine.

Keep bystanders away from equipment.

Do not operate or transport equipment while

under the influence of alcohol or drugs.

Keep hands, feet, hair, and clothing away from

equipment while engine is running. Stay clear of all

moving parts.

Never allow riders on power unit or attachment.

Never direct discharge toward people, animals,

or property.

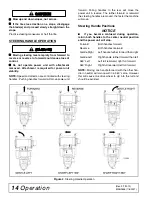

Moving steering levers rapidly from forward to

reverse or reverse to forward could cause loss of

control.

Look down and to the rear and make sure area

is clear before operating in reverse.

Do not stop, start, or change directions sud-

denly on slopes.

Before dismounting power unit, follow these

steps: lower attachment to ground, shut off PTO,

set parking brake, shut off engine, position steer-

ing levers to neutral swing-out position, and

remove key.

Do not drive or operate mower in tilt-up posi-

tion. Power unit stability is not adequate and result-

ing loads can damage or cause failure of tilt-up

mechanism.

Do not operate PTO during transport.

Remove accumulated debris from this equip-

ment, power unit, and engine to avoid fire hazard.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

Start engine from operator's seat after disen-

gaging power unit PTO and placing steering levers

in neutral.

Stop power unit and equipment immediately

upon striking an obstruction. Turn off engine,

remove key, inspect, and repair any damage before

resuming operation.

WARNING

WARNING

CAUTION

Summary of Contents for Mov'n Machine FZ25D

Page 1: ...OPERATOR S MANUAL MOW N MACHINE Rev 9 1 2015 FZ25D Power Unit MAN0646 ...

Page 30: ...30 Dealer Check Lists MAN0646 Rev 11 5 2007 NOTES ...

Page 32: ...32 Parts MAN0646 Rev 11 5 2007 FZ25D FRAME ASSEMBLY Rev 8 22 2008 ...

Page 34: ...34 Parts MAN0646 Rev 11 5 2007 FZ25D ENGINE ASSEMBLY Rev 6 5 2014 ...

Page 38: ...38 Parts MAN0646 Rev 11 5 2007 PTO CLUTCH PUMP ASSEMBLY Rev 3 20 2013 ...

Page 42: ...42 Parts MAN0646 Rev 11 5 2007 BRAKE ASSEMBLY ...

Page 44: ...44 Parts MAN0646 Rev 11 5 2007 FZ25D WIRING DIAGRAM KUBOTA Rev 8 22 2008 ...