Dealer Service

21

MAN0646 (Rev. 11/5/2007)

DEALER SERVICE

The information in this section is written for dealer ser-

vice personnel. The repair described here requires

special skills and tools. If your shop is not properly

equipped or your mechanics are not properly trained in

this type of repair, you may be time and money ahead

to replace complete assemblies.

Before performing any service or maintenance,

lower attachment to ground, turn off power unit

engine, remove key, and disconnect battery ground

cable (negative -).

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

TROUBLESHOOTING HYDROSTATIC

PUMP

Loss of Power in Transmission

1.

Make sure transmission fluid is correct.

2.

Make sure hydrostatic pump and fan blades are

clean.

NOTE:

Overheating can cause loss of power or

fluid leaks from excess fluid expansion.

3.

Make sure dump valves are tightened down.

NOTE:

Transmission fluid can leak by the dump

valve if by-pass is not tight. Tighten hex head if

dump valves are loose.

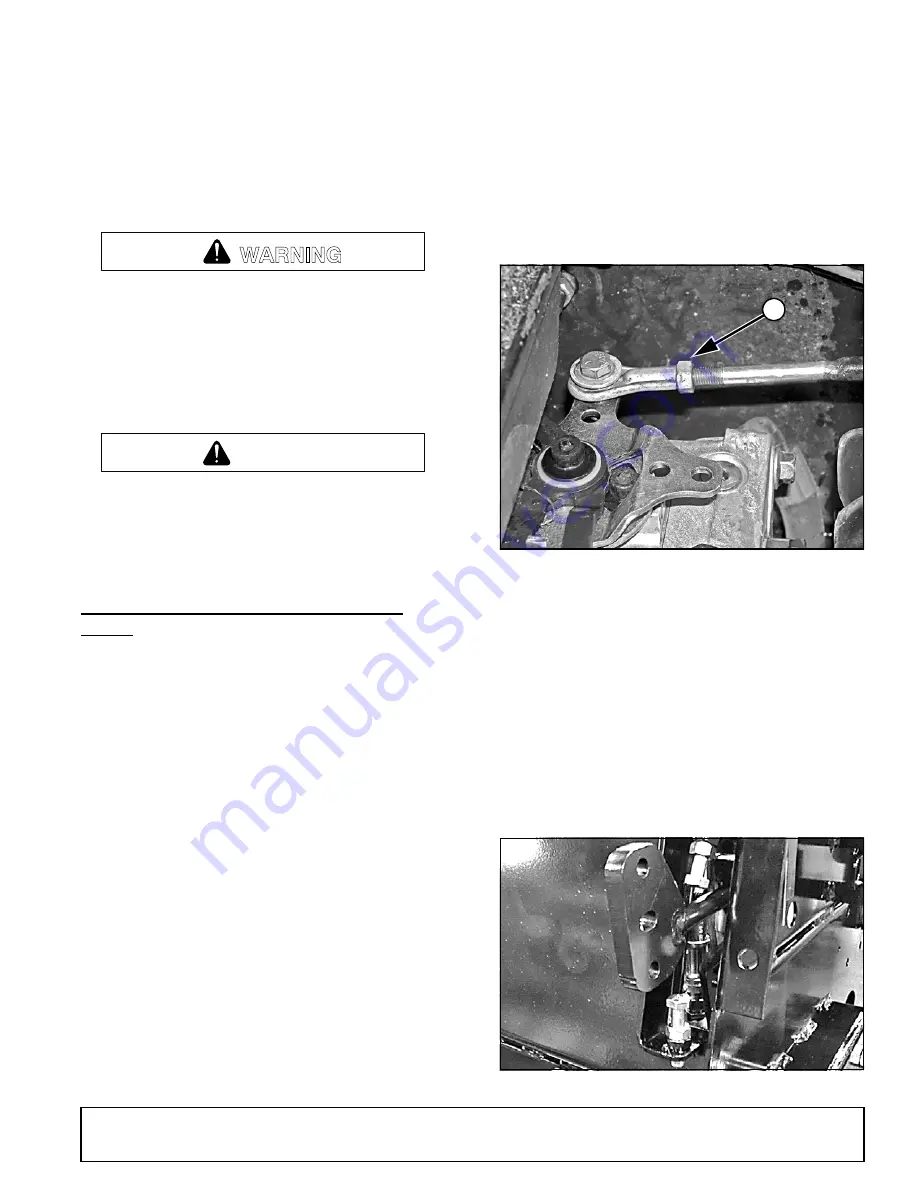

No Positive Neutral Position

If drive wheels travel forward or reverse when steering

handles are in the NEUTRAL position (pivoted out-

ward), adjustment of hydrostatic pumps is necessary.

1.

Block up power unit frame so both drive wheels are

off the ground.

2.

Release parking brake.

3.

Loosen jam nut (1) on linkage rod as shown in

Figure 10.

4.

Place steering handles in the NEUTRAL position

(pivoted outward) and start engine.

5.

If drive wheels turn, turn rod out or in until wheel

stops.

6.

Tighten jam nut.

7.

Repeat steps 3 through 6 for other hydrostatic

pump control arm.

Figure 10

. Jam Nut on Linkage Rod, Left Pump

Straight Line Travel Adjustment

1.

Check tire pressure; tires must have equal air

pressure.

2.

Check travel; drive forward with both steering

handles full forward at half throttle.

• If travel is not straight, adjust steering handle stop

bolt on opposite side of turn.

• If power unit turns to the left, raise steering stop

bolt on the right.

• If power unit turns to the right, raise steering stop

bolt on the left.

Figure 11

. Left Side Steering Stop Bolts

WARNING

CAUTION

1

DP4

Summary of Contents for Mov'n Machine FZ25D

Page 1: ...OPERATOR S MANUAL MOW N MACHINE Rev 9 1 2015 FZ25D Power Unit MAN0646 ...

Page 30: ...30 Dealer Check Lists MAN0646 Rev 11 5 2007 NOTES ...

Page 32: ...32 Parts MAN0646 Rev 11 5 2007 FZ25D FRAME ASSEMBLY Rev 8 22 2008 ...

Page 34: ...34 Parts MAN0646 Rev 11 5 2007 FZ25D ENGINE ASSEMBLY Rev 6 5 2014 ...

Page 38: ...38 Parts MAN0646 Rev 11 5 2007 PTO CLUTCH PUMP ASSEMBLY Rev 3 20 2013 ...

Page 42: ...42 Parts MAN0646 Rev 11 5 2007 BRAKE ASSEMBLY ...

Page 44: ...44 Parts MAN0646 Rev 11 5 2007 FZ25D WIRING DIAGRAM KUBOTA Rev 8 22 2008 ...