Owner Service

17

MAN1192 (1/13/2017)

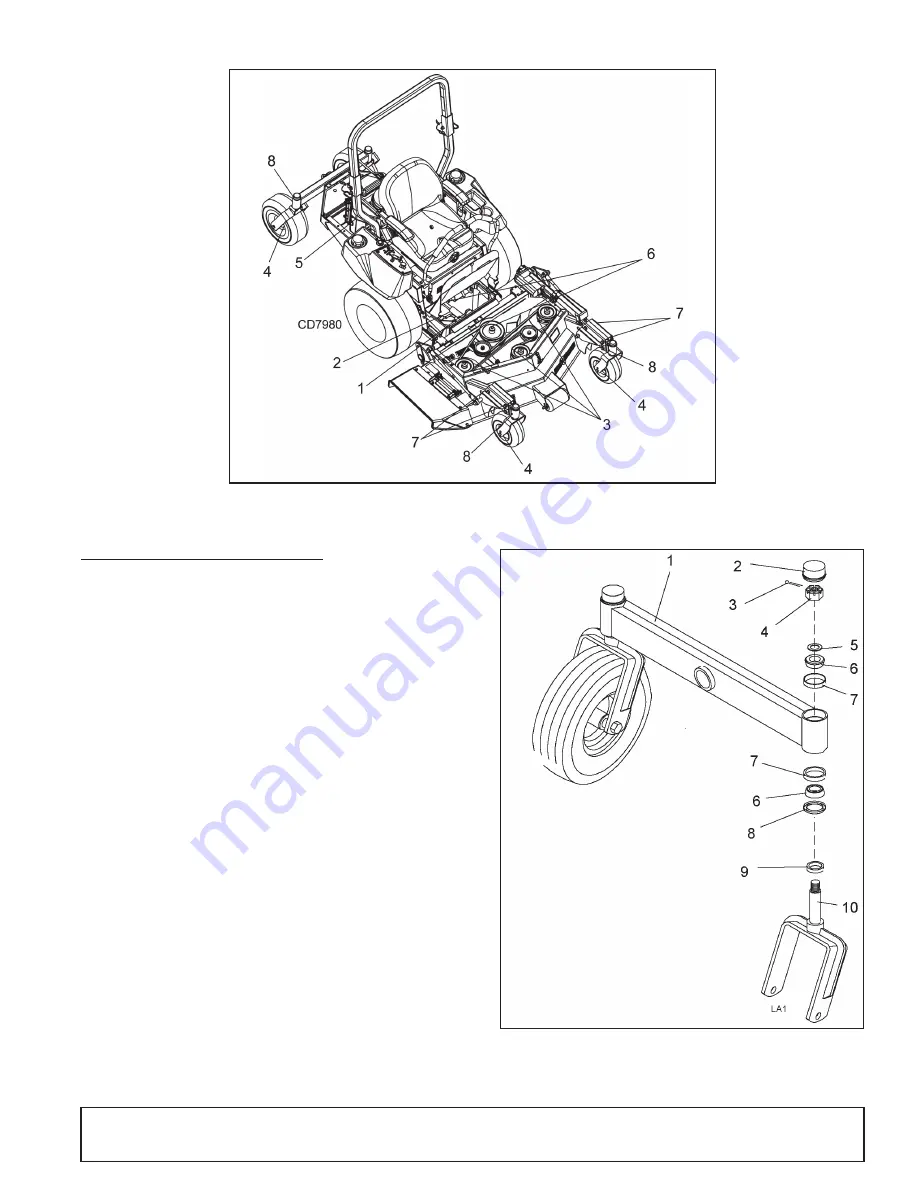

Figure 4

. Lubrication Diagram

TAILWHEEL MAINTENANCE

Once a year, disassemble tailwheel assembly and

inspect roller bearings:

1.

Remove dust cap (2) from top of tailwheel

assembly (1).

2.

Remove cotter pin (3) and slotted hex nut (4).

3.

Remove wheel fork (10), bearing cones (6) and

remaining hardware from assembly.

4.

Inspect bearing cones (6) and bearing cups (7) for

wear and replace if necessary. Replace seals and

washers as necessary.

5.

Pack bearing cones (6) with a good grade wheel

bearing grease.

6.

Install wheel fork (10) bearing cones (6) and

remaining hardware into assembly as shown.

7.

Set bearings by torquing nut to 26 lbs-ft. All bearing

free play should be removed.

NOTE:

Proper bearing adjustment is essential to good

bearing life.

If bearings are loose, casters will wobble and/or slap

side-to-side.

If bearings are overtightened, loosen hex nut and rap

shaft with a lead hammer to loosen bearings. Readjust

bearings until proper setting is obtained.

Figure 5

. Tailwheel Assembly (Typical)

1. Tailwheel assembly

2. Dust cap

3. Cotter pin

4. Slotted hex nut

5. Bushing washer 3/4 x 14 GA

6. Bearing cone

7. Bearing cup

8. Seal

9. Spacer

10. Wheel fork

Summary of Contents for MOW'N MACHINE FZ22-2

Page 1: ...OPERATOR S MANUAL MOW N MACHINE MAN1192 1 13 2017 FZ22 2 TM ...

Page 28: ...28 Dealer Check Lists MAN1192 1 13 2017 NOTES ...

Page 30: ...30 Parts MAN1192 1 13 2017 FZ22 2 FRAME ASSEMBLY ...

Page 34: ...34 Parts MAN1192 1 13 2017 PTO CLUTCH PUMP ASSEMBLY ...

Page 38: ...38 Parts MAN1192 1 13 2017 FZ22 2 WIRING DIAGRAM ...