Dealer Service

23

MAN1192 (1/13/2017)

Troubleshooting Deck Safety Switch

1.

Pull handlebars in with deck in lowest cutting

height position (1), see Figure 10.

2.

Check that switch is making contact with the height

gauge.

3.

Check that the wires are properly hooked up to

power unit.

4.

Adjust switch bracket location on actuator if

needed (four screws). Make sure height screw

does not bottom out on slot in either direction when

raising or lowering deck.

5.

Check that screws holding switch to bracket are

not too tight and holding lever open.

6.

Adjust safety switch lever or replace switch if

necessary.

7.

After adjustments, check that engine cuts out with

deck partially raised.

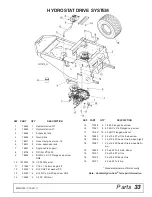

HYDROSTAT DRIVE REMOVAL

1.

Place power unit on a level surface and remove

key.

2.

Place power unit on stands to allow access to

bottom of the machine and remove drive wheels.

3.

Remove brake linkage from control arm on

hydrostat.

4.

Remove brake arm actuator and spring from brake

arm.

5.

Remove expansion tank hose from hydro.

6.

Loosen idler spring and remove belt.

7.

Remove two outer screws, washers and nuts.

8.

At front of machine, remove two screws and nuts

attaching small L bracket.

9.

At rear of machine, remove two screws and nuts

attaching small L bracket.

10.

While supporting hydro (each hydro weighs

approximately 33 pounds), remove front and rear

screws and nuts.

11.

Lower hydro down and out from under unit.

12.

For repair parts information, contact Hydro-Gear

®

at 1-877-728-7410 for nearest authorized dealer.

HYDROSTAT DRIVE INSTALLATION

1.

Position hydro under frame and carefully raise up

into position.

2.

Install two outer screws, washers and nuts finger

tight.

3.

Install small L bracket at the front and rear using

long bolts through frame loosely.

4.

Install screws and nuts in the front and rear of the

frame finger tight.

5.

With hydro positioned squarely, tighten small L

bracket nuts and then the longer screws through

frame.

6.

Tighten outer nuts.

7.

Install belt and tighten spring to proper belt tension.

8.

Install expansion tank hose.

9.

Install brake arm actuator and spring on brake arm.

No adjustment necessary if arm was not moved.

10.

Install brake linkage from control arm to hydrostat.

11.

Proceed to oil change maintenance for proper oil

change and pump purging.

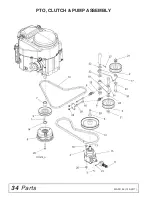

BELT REMOVAL

1.

Remove key from switch.

2.

Loosen idler spring bolt, and derail belt from

pulleys.

3.

Remove belts.

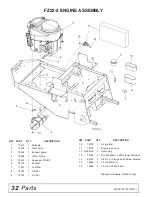

ENGINE REMOVAL

1.

Disconnect throttle cable, battery cables, hoses,

fuel line, and electrical wires from engine.

2.

Remove the four engine mounting bolts from

bottom of power unit frame.

3.

Remove belts from the engine pulleys. See Belt

Removal.

4.

Remove exhaust.

5.

Lift engine from the power unit frame.

NOTE:

Contact your authorized engine dealer for

parts and repairs.

PARKING BRAKE ADJUSTMENT

NOTE:

Hydrostatic system parking brake is similar to

automotive style parking pawl and is not a service

brake. Brake system is for parking of unit and emer-

gency use only. The drive wheel may have to rotate

slightly to engage pawl in locking ring (usually less the

3 degrees of wheel rotation).

NOTE:

Parking brake is adjusted from the factory and

should require no maintenance unless the system parts

are replaced.

NOTE:

Adjust right and left brakes individually.

1.

With drive wheels off of the ground and brake

handle is in ON position, check to see if drive

wheel rotates.

2.

If drive wheel rotates and park brake does not

engage, remove screw from top of park brake

release link and free park brake release rod. (If

Summary of Contents for MOW'N MACHINE FZ22-2

Page 1: ...OPERATOR S MANUAL MOW N MACHINE MAN1192 1 13 2017 FZ22 2 TM ...

Page 28: ...28 Dealer Check Lists MAN1192 1 13 2017 NOTES ...

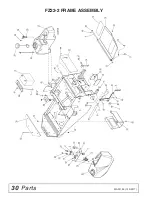

Page 30: ...30 Parts MAN1192 1 13 2017 FZ22 2 FRAME ASSEMBLY ...

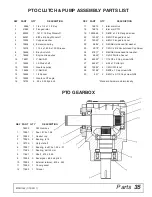

Page 34: ...34 Parts MAN1192 1 13 2017 PTO CLUTCH PUMP ASSEMBLY ...

Page 38: ...38 Parts MAN1192 1 13 2017 FZ22 2 WIRING DIAGRAM ...