18 Owner Service

20944 (Rev. 2/3/2006)

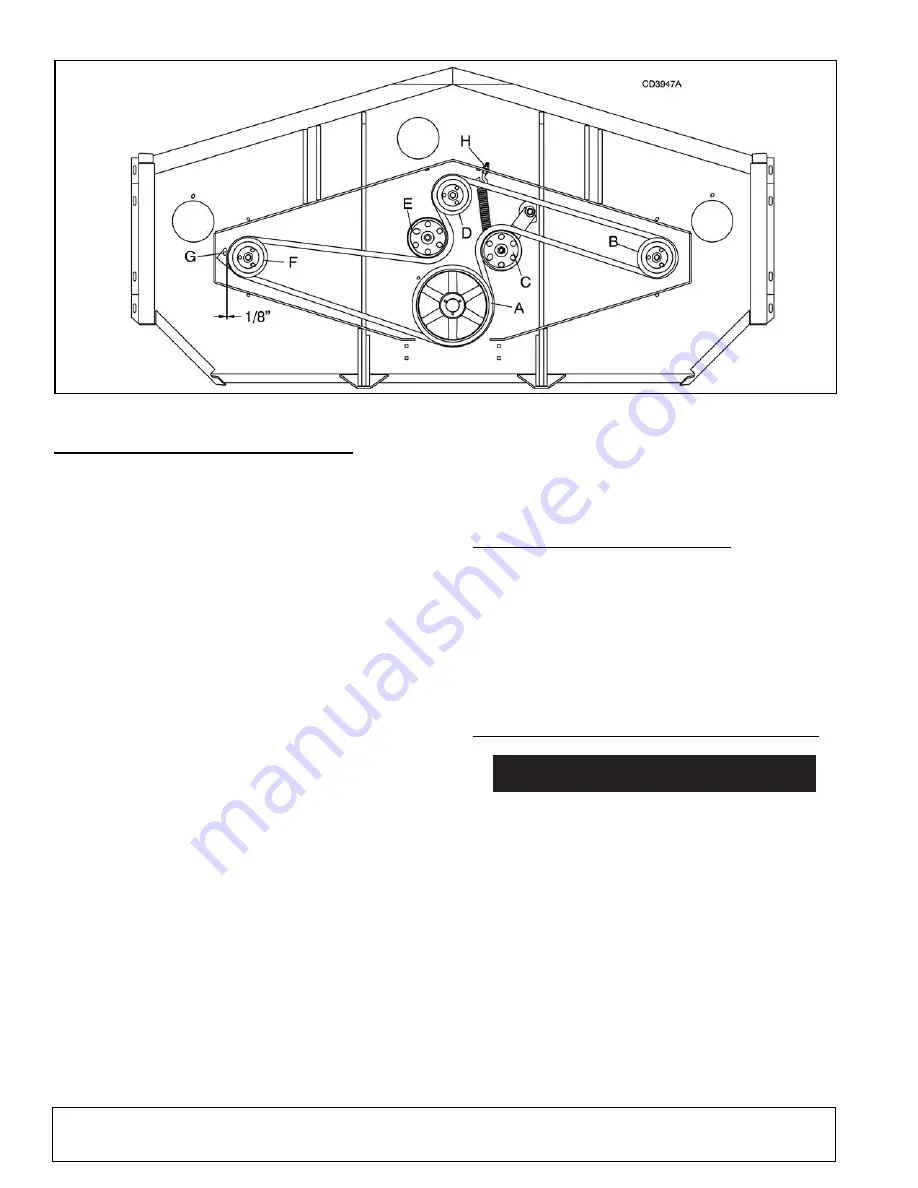

Figure 10. Belt Installation

BELT REPLACEMENT (FIGURE 10)

One of the major causes of belt failure is improper

installation. Before a new belt is installed, check pulley

shafts and bearings for wear. Check pulley grooves for

cleanliness. Make sure spindles turn freely and without

wobble. If grooves require cleaning, use a cloth moist-

ened with a non-flammable, non-toxic degreasing

agent or commercial detergent and water.

Avoid excessive force during installation. Do not use

tools to pry belt into pulley groove. Do not roll belt over

pulleys to install. This can cause hidden damage and

premature belt failure.

NOTICE

■

Use care when installing or removing belt from

spring-loaded idler in step 6. Springs store energy

when extended and, if released suddenly, can

cause personal injury.

Belt replacement is accomplished in these steps:

1. Loosen nut and swing belt guide (G) away from

pulley (F).

2. Loosen nut on eyebolt (H) to relax tension in

spring.

3. Slide belt under and around drive pulley (A).

4. Route belt around pulley (F), idler (E) and pulley

(D) as shown.

5. Make sure belt is on drive pulley (A) and route belt

around spring-loaded idler (C).

6. Grasp belt between spindle pulley (B), spring-

loaded idler (C) and spindle pulley (D). Pull spring-

loaded idler with belt and route belt over pulley (B).

7. Tighten nut on eyebolt (H). Make sure spring-

loaded idler arm pivots freely with belt installed.

8. Set belt guide (G) 1/8" away from belt. Tighten to

85 lbs-ft.

SHEAR BOLT REPLACEMENT

NOTICE

■

Always use approved 1/2" NC x 3" grade 2

shear bolt as a replacement part. Using a hardened

bolt or shear pin may result in damage to driveline

or gearbox.

Rotate driveline to align holes in yoke and shaft. Install

shear bolt and secure with lock nut.

CHAIN OR RUBBER SHIELDING REPAIR

Full chain or rubber shielding must be installed

when operating in populated areas or other areas

where thrown objects could injure people or dam-

age property.

• If this machine is not equipped with full chain

or rubber shielding, operation must be stopped

when anyone comes within 300 feet (92 m).

• This shielding is designed to reduce the risk

of thrown objects. The mower deck and protec-

tive devices cannot prevent all objects from

escaping the blade enclosure in every mowing

condition. It is possible for objects to ricochet

and escape, traveling as much as 300 feet (92 m).

A

DANGER

(Rev. 4/28/2006)