Owner Service 19

20944 (Rev. 2/3/2006)

Chain Shielding Repair

Inspect chain shielding each day of operation and

replace any broken or missing chains as required.

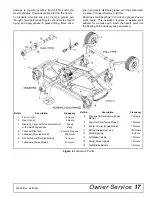

SIDE SKID REPAIR

Side skids are replaceable. Check them periodically

and replace as necessary.

Figure 11. Side Skid Repair

BLADE SERVICING

Your dealer can supply genuine replacement

blades. Substitute blades may not meet original

equipment specifications and may be dangerous.

Make certain all movement of equipment com-

ponents has stopped before approaching for ser-

vice.

Low suction and general purpose suction blades are

available. Use low suction blades in sandy areas where

abrasive action could cause excessive blade wear.

General purpose suction blades are recommended for

all other applications.

Inspect blades before operation for condition and

ensure they are securely fastened. Replace blades that

are bent, excessively nicked, worn or have any other

damage. Small nicks may be ground out when sharp-

ening.

Replace blades on a spindle in pairs; an old blade and

a new blade may vary excessively in weight and cause

vibration. Never mix blade types.

Blade Sharpening

Follow the original sharpening pattern. Make an effort

to maintain balance on both blades from a spindle by

grinding the same amount from them. Blades that vary

excessively in weight can cause vibration.

Figure 12. Blade Sharpening

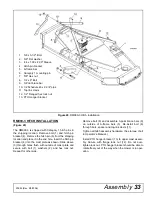

Blade Removal

This mower is equipped with quick change blades.

Open blade access cover, loosen bolt (5) and rotate

blade lock (4) to allow for removal of blade pin (3).

Remove blade (2). Rotate spindle and remove opposite

blade in same manner.

Blade Installation

Make sure to position blade so the cutting edge leads

in a counter-clockwise rotation. Install blade (2), then

place blade pin (3) in hole and rotate blade lock (4) to

secure blade. Tighten bolt (5). Rotate spindle and

install opposite blade in same manner. Repeat for

remaining spindles.

Figure 13. Blade Installation and Lock

WHEEL BEARING MAINTENANCE

RM990-3 ONLY

At least once each mowing season or 250 hours of

operation, whichever occurs first, the bearings in the

tailwheel should be removed, cleaned and repacked.

Replace bearings and cones if broken or worn exces-

sively.

Install the wheel in the wheel yoke and tighten the inner

nut until there is a slight bearing drag (similar to auto-

mobile wheels). Hold the inner nut and tighten the lock

nut against it to maintain bearing adjustment.

1. Side skid bar

2. 3/8 x 1-1/4" Clipped

head bolt

3. 3/8 " Lock washer

4. 3/8" Hex lock nut

A

CAUTION

1. Blade spindle

2. Blade

3. Blade pin

4. Blade lock

5. 1/2 x 3/4" Nylock

bolt

(Rev. 4/28/2006)