Dealer Service 27

20944 (Rev. 2/3/2006)

nut (19). If nut is too tight to remove with a spanner

wrench, loosen with a punch and hammer.

Carefully remove vertical shaft seal (18) to prevent

damage to shaft threads and seal bore.

Remove gearbox from vise. Use care when removing

horizontal shaft seal (1) and retaining ring (2) to pre-

vent damage to shaft seal surface and housing bore.

Place puller (20) over horizontal shaft (6) and insert a

1/2" bolt or rod through horizontal shaft shear bolt hole.

Tighten puller bolts evenly to remove shaft from hous-

ing.

Place housing upside-down in a press and remove ver-

tical shaft (14) by pressing through the top of the hous-

ing. Remove bearing cone (15) from vertical shaft (14)

with a spreader. Remove all cups from housing with a

puller or by carefully driving them out with a punch.

Inspect gears for excessive wear. Gears are forged

and surfaces will appear rough, even when new. Some

wear is normal. Gears will show more wear on the

loaded side and the pattern should be smooth.

Inspect both gear shafts and stake nut for grooves,

nicks or bumps where seals seat. Replace if damage

cannot be repaired by resurfacing with emery cloth.

Clean gearbox housing and inspect for damage.

Replace if cracks are found.

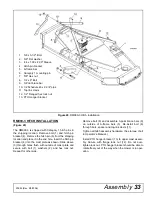

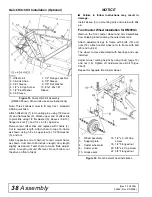

Gearbox Assembly

(S/N 788882 and prior, Figure 23)

Press cups (8 & 16) into housing until they seat tightly

against machined shoulders.

Press bearing cone (15) onto vertical gear shaft (14)

and seat it against gear.

Insert vertical gear shaft into housing. Invert housing in

a press and place supports under gear to hold bearing

cone (15) against cup (16). Press bottom bearing cone

(15) onto shaft until all free play is removed and there is

a slight drag when rotating housing on shaft (similar to

setting automobile front wheel bearings). If bearings

are too tight, loosen by holding housing and rapping on

end of vertical gear shaft (14) with a shot hammer or

equivalent.

Install O-ring (17) into groove on vertical gear shaft (14)

next to bearing cone (15). Place a small bead of gasket

sealer on top of O-ring.

Use the proper size tubing to press against the outside

edge of seal to prevent seal damage. Apply gasket

sealant to seal bore and press output shaft seal (18)

into housing until it seats against housing shoulder.

Coat inner portion of seal with grease.

Thread stake nut (19) onto shaft (14) in through seal

(18). Tighten until nut is snug against bearing cone

(15). Use a punch to stake the lip of stake nut (19) into

shaft (14) keyway.

Insert shaft (6) through top of housing out through hori-

zontal hole, then set bearing (7) into cup (8). Press

bearing (5) onto gear shaft (6). Do not use excessive

force to seat bearing.

Place bearing cup (4) over horizontal shaft (6) and

press into housing until there is a slight drag on bear-

ings when shaft is rotated (similar to setting automobile

front wheel bearings). When you have bearings

adjusted, select shims from shim kit (3) and place on

top of bearing cup (4) until they are flush with bottom of

snap ring groove in horizontal shaft (6), then install

snap ring (2).

Apply gasket sealant to housing seal bore and press

seal (1) into housing until it seats against snap ring or is

flush with housing.

Apply gasket sealant to top of housing flange, replace

top cover and secure with bolts (10) and washers (9).

Attach gearbox to gear stand and torque mounting

bolts.

Remove the dipstick and pour in one quart of gear

lube. Wait five minutes and add an additional pint and

one half. Allow an additional five minutes for the lube to

flow through the bearings, then check to make sure

half of the horizontal gear shaft is covered. Replace the

dipstick.