Dealer Service 27

MAN0475 (9/21/2005)

19. Check gearbox housing for leaks by plugging all

holes except one. Apply 4 psi compressed air and

immerse the gearbox in water to verify that there

are no leaks.

20. Remove gearbox from water and dry off with

compressed air. Add SAE 80W or 90W EP oil until

it runs out of side level hole. Tighten all plugs.

Gearbox Installation

NOTE: Gearbox is heavy: do not attempt to move with-

out mechanical assistance.

1. Set gearbox on gearbox stand and fasten with

bolts and nuts. Torque bolts to 175 lbs-ft.

2. Attach drive sheave to output shaft. Secure using

castle nut and hardware previously removed.

3. Attach gearbox stand to mower using four flanged

1/2" lock nuts.

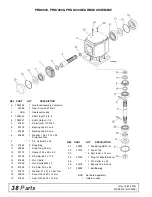

Drive Sheave Installation

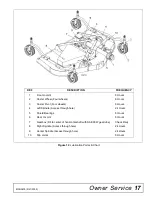

Refer to Figure 21.

1. When gear stand is installed on mower, dimension

A (from the top of the mower deck to the center line

of the drive pulley) must be 2-7/16" (±1/32"). This is

a critical dimension and must be carefully adjusted

for proper belt life. Add or subtract shim washers

under idler pulley (3) to align with drive pulley (4).

2. Tighten gear stand hardware.

3. Fill gearbox half full with SAE 90W gear lube.

4. Check level after waiting five minutes to permit

lube to work through bearings. Add lube, if

necessary, until gearbox is half full.

5. Replace driveline shield. Attach driveline to

gearbox.

Figure 21. Drive Sheave Installation

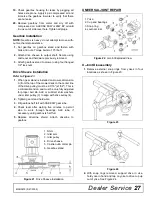

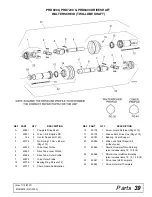

UNIVERSAL JOINT REPAIR

Figure 22. U-Joint Exploded View

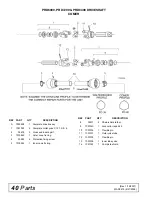

U-Joint Disassembly

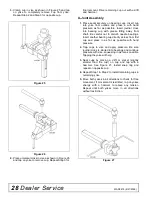

1. Remove external snap rings from yokes in four

locations as shown in Figure 23.

.

Figure 23

Figure 24

2. With snap rings removed, support drive in vise,

hold yoke in hand and tap on yoke to drive cup up

out of yoke. See Figure 24.

1. Shim

2. Idler arm

3. Idler pulley

4. Drive sheave

5. Castle nut & cotter pin

6. Gearbox stand

1. Yoke

2. Cup and bearings

3. Snap ring

4. Journal cross