Dealer Service

19

MAN1260 (4/09/2018)

6.

Press gear (5) onto output shaft (4) and secure with washer (17), castle

nut (14), and cotter pin (9).

7.

Apply grease to lower seal lips (18) and press seal over output shaft (4),

using a tube of the correct diameter. Be sure not to damage the seal lip.

Press in housing so that seal is recessed.

8.

Insert protective washer (8) by hand. Install snap ring (21) and position it

together with dual lip seal (18) by pressing it into position. Verify that

snap ring is seated correctly.

9.

Press bearing (7) into the housing, using a round tube of the correct

diameter and a hand press. Secure with shim (13) and snap ring (10).

10.

Secure snap ring (11) on input shaft (3) if not already secure.

11.

Place gear (1) through top of housing and align gear (1) and gear (5) so

that gear teeth are a match.

12.

While holding gear (1) in place, slide input shaft (3) through gear (1) and

bearing (7). Align splines on shaft (3) and gear (1).

13.

Slide spacer (12) over input shaft (3) and press bearing onto input shaft

(3), using a round tube of the correct diameter and a hand press.

14.

Slide shim (13) over input shaft (3) and secure with snap ring (10).

15.

Check input shaft end float by moving the input shaft (3) by hand. If end

float is higher than .3 mm (0.012”), insert shim between input shaft (3)

and rear bearing (7). Repeat until end float is less than .3 mm (0.012”).

Check rotational torque by hand. The torque should be less than .25 N-m

(2.2 lbs-inch).

16.

Check that the gear backlash is between .15 mm (0.006”) and .41 mm

(0.016”). You should not have to adjust the backlash.

17.

Press in input oil seal (19), using tube of correct diameter. Be careful not

to damage seal lip.

18.

Press oil cap (20) on to cover the rear of housing, using a tube of the

correct diameter.

19.

Check gearbox housing for leaks by plugging all holes except one. Apply

27.6 kPa (4 psi) compressed air and immerse the gearbox in water to

verify that there are no leaks.

20.

Remove gearbox from water and dry off with compressed air. Add SAE

80W or 90W EP oil until it runs out of side level hole. Tighten all plugs.

Gearbox Installation

NOTE:

Gearbox is heavy: do not attempt to move without mechanical assis

-

tance.

1.

Set gearbox on gearbox stand and fasten with bolts and nuts. Torque

bolts to 237 N-m (175 lbs-ft).

2.

Attach drive sheave to output shaft. Secure using castle nut and

hardware previously removed.

3.

Attach gearbox stand to mower using four flanged 1/2" lock nuts.

DRIVE SHEAVE INSTALLATION

1.

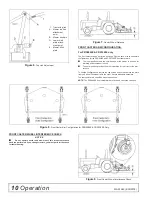

When gear stand is installed on mower, dimension A (from the top of the

mower deck to the center line of the drive pulley) must be 61.9 ±.8 mm

(2-7/16" ±1/32"). This is a critical dimension and must be carefully

adjusted for proper belt life. Add or subtract shim washers under idler

pulley (3) to align with drive pulley (4).

2.

Tighten gear stand hardware.

3.

Fill gearbox half full with SAE 90W gear lube.

4.

Check level after waiting five minutes to permit lube to work through

bearings. Add lube, if necessary, until gearbox is half full.

5.

Replace driveline shield. Attach driveline to gearbox.

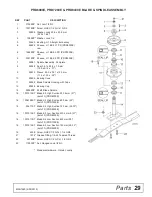

Figure 21

. Drive Sheave Installation

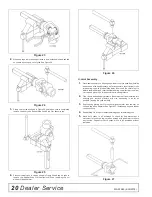

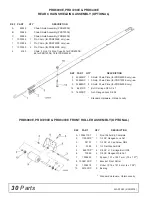

UNIVERSAL JOINT REPAIR

Figure 22

. U-Joint Exploded View

U-Joint Disassembly

1.

Remove external snap rings from yokes in four locations as shown in

Figure 23.

1. Shim

2. Idler arm

3. Idler pulley

4. Drive sheave

5. Castle nut & cotter pin

6. Gearbox stand

1. Yoke

2. Cup and bearings

3. Snap ring

4. Journal cross

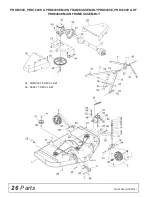

Summary of Contents for PRD6000E

Page 1: ...OPERATOR S MANUAL PREMIER REAR DISCHARGE MOWERS MAN1260 4 09 2018 PRD6000E PRD7200E PRD8400E...

Page 7: ...Declaration of Conformity 7 MAN1260 4 09 2018 Declaration of Conformity...

Page 46: ...8 D claration de Conformit MAN1260 4 09 2018 Declaration of Conformity...

Page 71: ...Dichiarazione di conformit 7 MAN1260 09 04 2018 Dichiarazione di conformit...

Page 89: ...HOCHWERTIGE M HER MIT R CKSEITIGEM AUSWURF MAN1260 09 04 2018 PRD6000E PRD7200E PRD8400E...

Page 95: ...Konformit tserkl rung 7 MAN1260 09 04 2018 Konformit tserkl rung...

Page 113: ...PRINCIPAL CORTADORAS DE DESCARGA TRASERA MAN1260 09 4 2018 PRD6000E PRD7200E PRD8400E...

Page 119: ...Declaraci n de conformidad 7 MAN1260 09 4 2018 Declaraci n de conformidad...