Owner Service

21

MAN1331

(09/29/22)

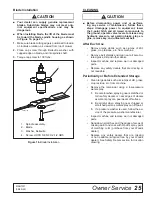

LUBRICATION INFORMATION

■ When lubricating telescoping PTO drives, keep

fingers out of shield access slots to prevent

injury.

Do not let excess grease collect on or around parts,

particularly when operating in sandy areas.

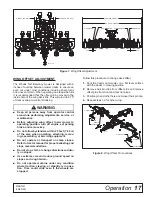

See Figure 10 and Figure 11 for lubrication points and

frequency or lubrication based on normal operating

conditions. Sever or unusual operating conditions may

require more frequent lubrication.

Use a lithium grease of #2 consistency with a MOLY

(molybdenum disulfide) additive for all locations unless

otherwise noted.

Fill blade spindles until grease purges out of the upper

seal.

Be sure to clean fittings thoroughly before attaching

grease gun. When applied according to the lubrication

chart, one good pump of most guns is sufficient.

Use SAE 90W gear lube in gearboxes. Check level of

oil in gearboxes using provided dipstick in vent plug or

until oil runs out of side plug.

Daily lubrication of PTO slip joints is necessary. Failure

to maintain proper lubrication can result in damage to

U-joints, gearboxes and/or drive shafts. Raise or lower

mower until grease fittings in PTO shields are exposed.

Insert grease gun through slots and apply grease to all

sides of shafts. Always stand clear of mower and wing

arm mechanism to avoid being pinched or crushed

should the mower or wing suddenly lower.

Raise and lower mower after applying grease so that it

spreads over the slip joint working area.

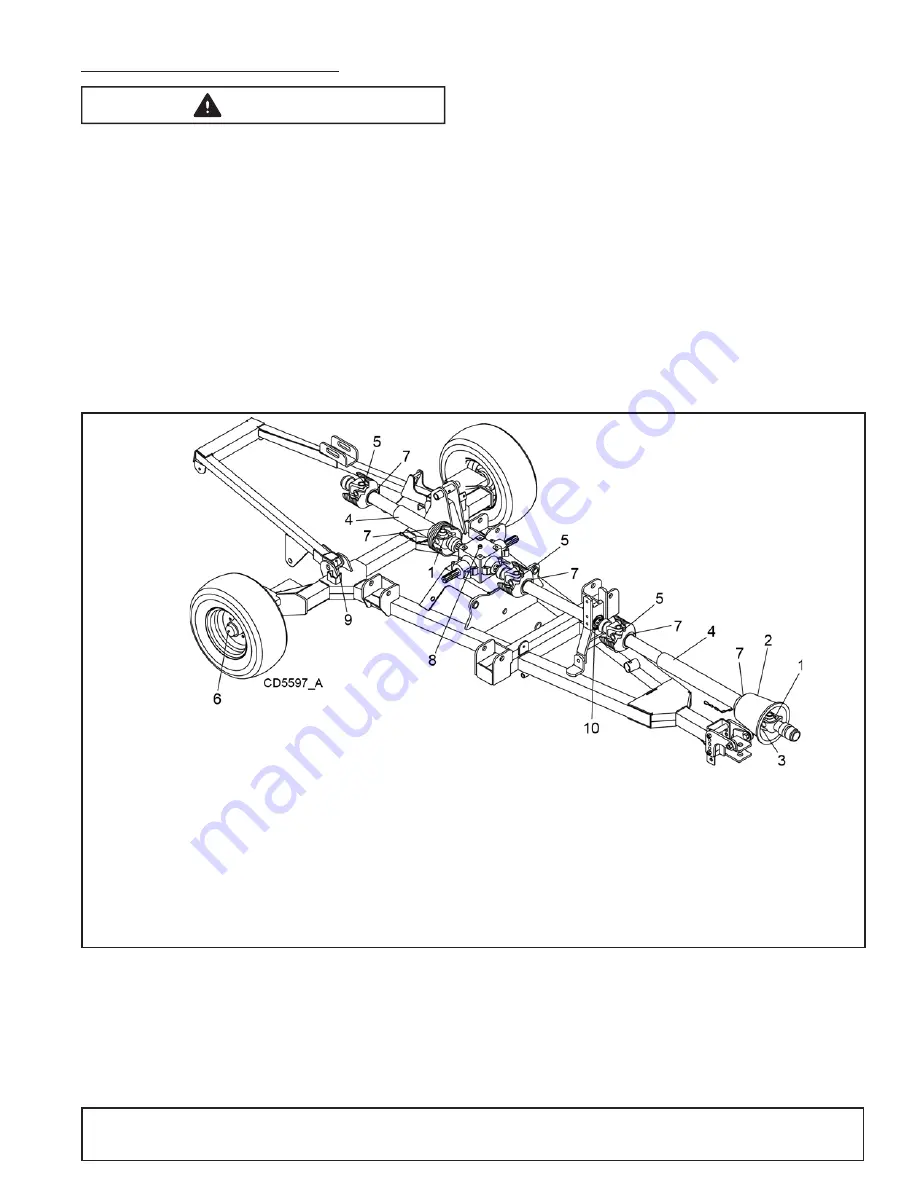

Figure 10.

Lubrication Points - Trailer

CAUTION

REF DESCRIPTION

FREQUENCY

1

Driveline U-Joint

8 Hours

2

Drive Carrier Bearing

8 Hours

3

CV Body

8 Hours

4

Telescoping Shaft

8 Hours

5

Rear Deck Pivot Arm

8 Hours

6

Transport Wheel Hub

8 Hours

7

Shield Bearing

8 Hours

8

Splitter Gearbox (Fill 1/2

full w/SAE 90W gear lube) Check For Leaks Daily