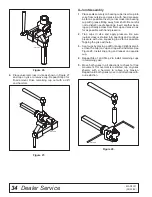

Dealer Service

29

MAN1331

(09/29/22)

Spindle Disassembly

1.

Place spindle assembly in press and press shaft

down through housing.

2.

Remove components from shaft.

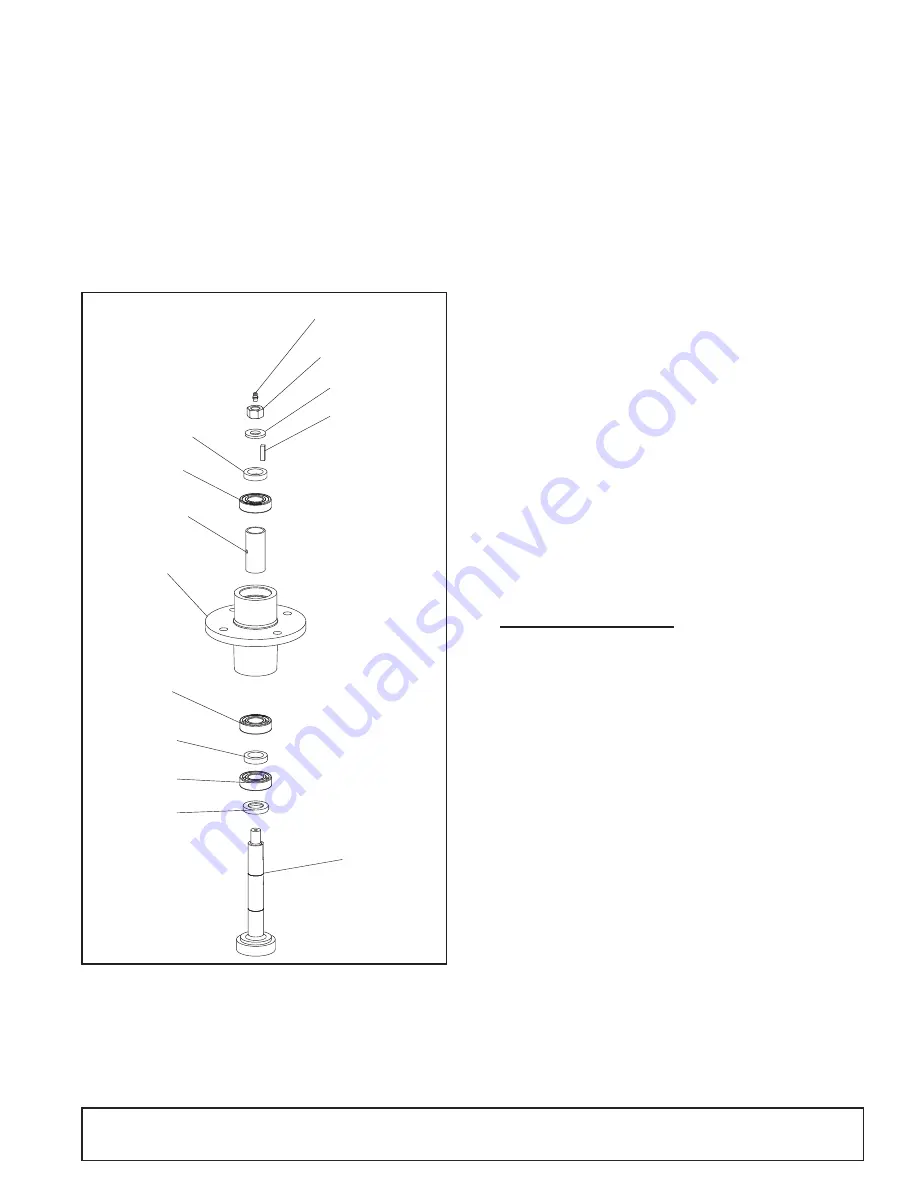

Spindle Assembly

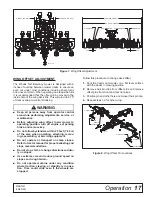

(Figure 18)

■ Improper positioning of seals can cause seal

damage. An improperly installed seal will leak

and could cause bearing failure.

Figure 18.

Spindle and Shaft Assembly

Bearing cones and cups are designed to work together.

It is important to position them so bearing cone taper

mates with cup taper.

1.

Install spacer (18) on shaft with bevel side down.

2.

Place bearing (16) on shaft with seal facing down.

3.

Install sleeve (12) and bearing (14) on shaft.

4.

Install sleeve (15) on shaft.

5.

Install shaft into spindle from bottom up.

6.

Install bearing (16) with seal up onto shaft.

7.

Install sleeve (12) key (11), washer (6) on shaft.

8.

Rotate housing on spindle shaft, checking for free

movement.

9.

Install grease fitting in spindle shaft and grease

spindle.

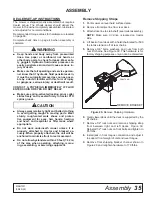

Spindle Installation

■ Pulley installation sequence is very important

for bearing life. Follow the sequence exactly.

1.

Install spindle through bottom of mower and secure

with four mounting bolts.

2.

Install pulley on spindle shaft.

3.

Install hardened washer and nut on pulley and tight-

en to 100 ft-lbs.

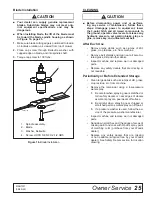

GEARBOX SERVICE

Gearbox Removal from Mower

(Figure 19)

1.

Disconnect and remove the rear driveline from the

gearbox.

2.

Remove vent plug and siphon gear lube from hous-

ing through this opening.

3.

Remove gearbox from mower deck by removing

four flanged lock nuts (16) and four carriage bolts

(21).

4.

Remove four cap screws (17) and remove shield

(13) from gearbox.

5.

Remove cotter pin (36) and castle nut (37) from out-

put shaft of gearbox.

6.

Remove sheave (8) from gearbox.

NOTICE

NOTICE

9

10

6

11

13

CD9273 AB

12

16

15

17

14

12

16

18