62 Parts

MAN1331

(09/29/22)

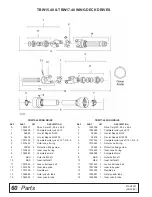

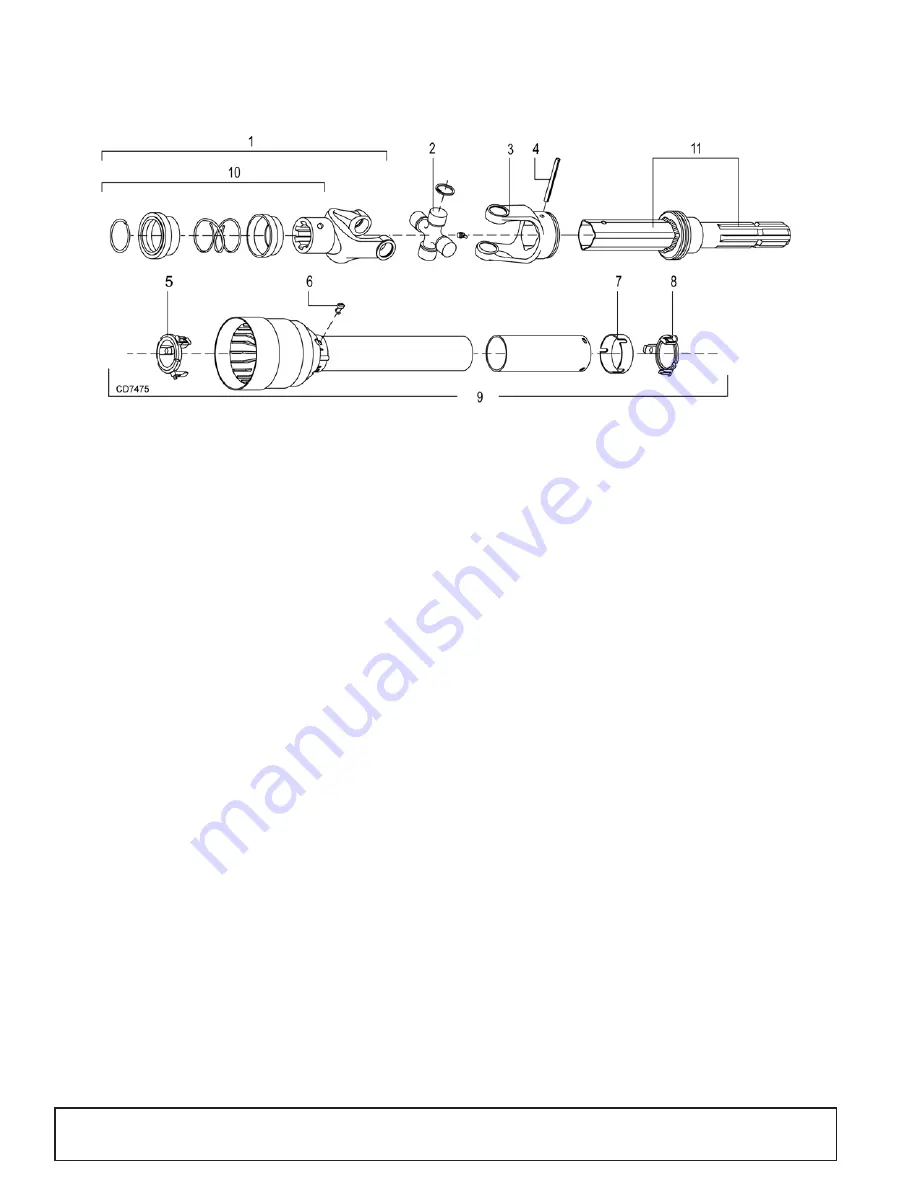

JACKSHAFT DRIVE ASSEMBLY

REF

PART

QTY

DESCRIPTION

A

1011759

Complete jackshaft drive assembly

1

1028775 1 Complete collar yoke

2

36990 1 U-Joint repair kit

3

1011756 1 Yoke, outer

4

1001330 1 Flexible pin

5

1028776 1 Outer bearing ring

6

30922 6 Retainer, shield

7

1011757 1 Centering ring

REF

PART

QTY

DESCRIPTION

8

1011755 1 Inner bearing ring

9

1011754 1 Shield, complete

(includes 5, 6, 7 & 8)

10

1001340 1 Lock collar repair kit

11

NSS 1 Jackshaft

NSS

Not Serviced Separately