38

Assembly

MAN0826 (8/31/2010)

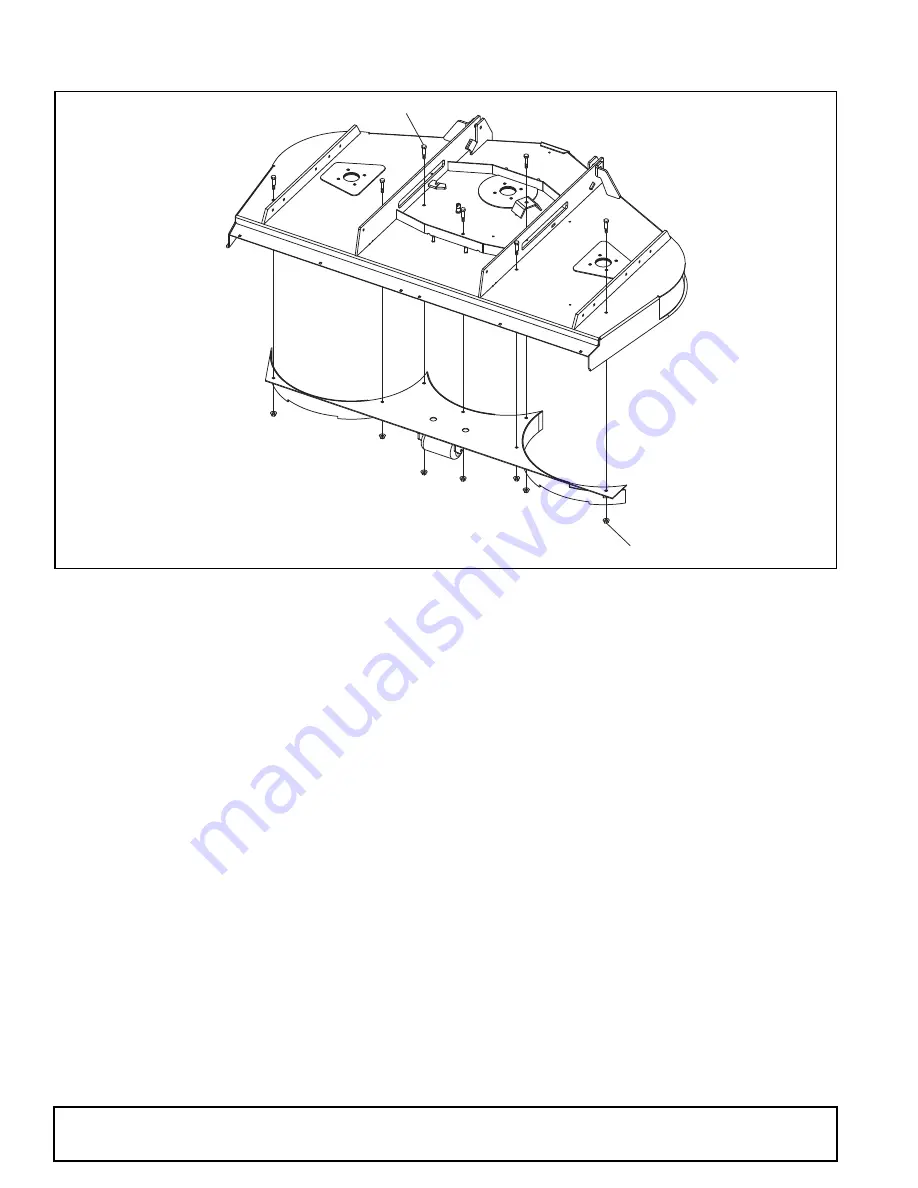

TBW180 & TBW204 Mulching Kit

Figure 34

. Mulching Kit Installation

NOTE:

Use high lift blades for best performance if tractor does not have enough horsepower for the high lift blades,

then use low lift blades.

1.

Using the tractor 3-point, or suitable lifting device,

carefully lower deck onto 4” - 6” high blocks at each

corner.

2.

Make sure deck is stable before proceeding.

3.

Wear safety glasses or goggles to prevent eye

injury while drilling holes.

4.

Clamp mulching kit in place. Make sure baffles are

completely closed-off by the kit.

5.

Inspect fit-up to confirm that there will be no

contact between blades and kit at any time. Failure

to do so will result in product damage and possible

injury.

6.

Mark the holes to be drilled.

7.

Once marked, remove the kit and carefully drill the

holes out using a 9/16” drill bit.

8.

After holes are drilled, bolt the kit into place

torqueing bolts to 85 lbs-ft.

x

x

x

x

2

1

1. 1/2 NC x 1-1/4 HHCS GR5

2. 1/2 NC Flange Lock Nut

Summary of Contents for Turf Batwing TBW144

Page 1: ...OPERATOR S MANUAL TURF BATWING MAN0826 Rev 11 15 2013 TBW144 TBW180 TBW204...

Page 39: ...Assembly 39 MAN0826 8 31 2010 NOTES...

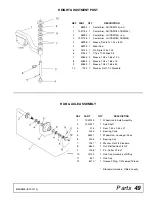

Page 42: ...42 Parts MAN0826 8 31 2010 TBW144 TBW180 TBW204 MAIN FRAME ASSEMBLY Rev 11 15 2013...

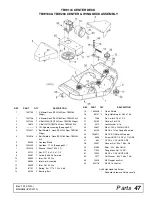

Page 44: ...44 Parts MAN0826 8 31 2010 TBW144 TBW180 TBW204 TRAILER ASSEMBLY Rev 11 15 2013...

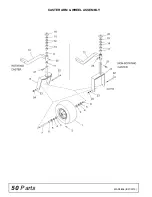

Page 50: ...50 Parts MAN0826 8 31 2010 CASTER ARM WHEEL ASSEMBLY...

Page 56: ...56 Parts MAN0826 8 31 2010 TBW144 TBW180 TBW204 REAR WING DECK DRIVES...