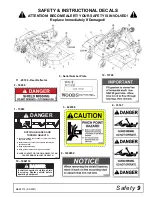

Owner Service

21

MAN1313 (3/3/2021)

Figure 17

. Belt Routing

BLADE SERVICING

Before dismounting power unit or performing

any service or maintenance, follow these steps:

disengage power to equipment, lower the 3-point

hitch and all raised components to the ground,

operate valve levers to release any hydraulic pres-

sure, set parking brake, stop engine, remove key,

and unfasten seat belt.

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

Frequently check blades. They should be sharp,

free of nicks and cracks, and securely fastened.

1.

Inspect blades before each use to determine that

they are mounted securely and are in good condi-

tion.

2.

Replace any blade that is bent, excessively nicked,

worn, or has any other damage. Do not repair.

3.

Small nicks can be ground out when sharpening.

Remove Blades

CAUTION!:

Do not handle blades with bare hands.

Wear gloves. Careless or improper handling may result

in inujury.

1.

Remove bolt (79), Figure 19, which has right hand

threads.

2.

Remove belville washers (78) and blade (77).

Sharpen Blades

NOTICE:

When sharpening blades, be sure to bal-

ance them. Unbalanced blades will cause exces-

sive vibration that can damage blade spindle

bearings. Vibration may also cause structural

cracks in mower housings.

Figure 18

. Blade Balancing

1.

Follow original sharpening pattern.

2.

Do not sharpen blade to a razor edge, but leave

approximately 1/64" blunt edge.

3.

Do not sharpen back side of blade.

4.

Sharpen both cutting edges equally to keep blade

balanced. Balance blade using the method shown

in Figure 18.

Install Blades

Your dealer can supply genuine replacement

blades. Substitute blades may not meet original

equipment specifications and may be dangerous.

NOTICE:

When installing blade, the lift of the blade

must be toward the spindle blade housing as

shown in Figure 19. Torque bolt (79) into shaft

assembly to 100 lbs-ft.

1.

Place blade over the bottom of the shaft assembly.

2.

Place Belleville washer (78) over blade and insert

blade bolt (79). Torque blade bolt to 100 lbs-ft.

Figure 19

. Blade and Spindle Assembly

WARNING

CAUTION

CAUTION