26

Dealer Service

MAN1313 (3/3/2021)

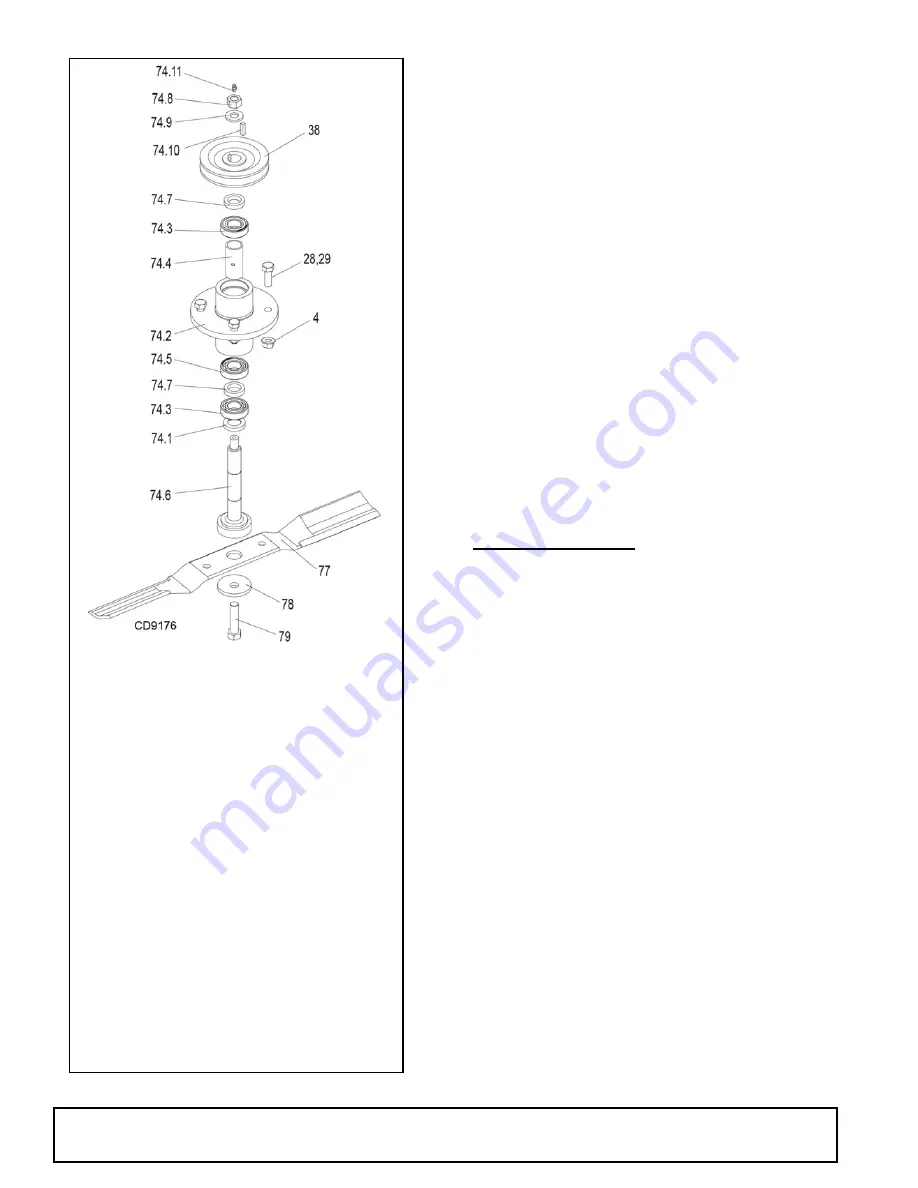

Figure 21

. Spindle Assembly

Disassemble Spindle

1.

Slide shaft (74.6), short spacer (74.1), lower bear-

ing (74.3), short bearing spacer (74.7), middle

bearing (74.5), and long spacer (74.4) out the bot-

tom of spindle housing (74.2).

2.

Remove upper bearing (74.3) from top of spindle

housing.

3.

Inspect parts and replace as needed.

Assemble Spindle

1.

Slide short spacer (74.1) and lower bearing (74.3)

over spindle shaft (74.6) with bearing seal facing

down.

2.

Slide short bearing spacer (74.7), middle bearing

w/o seal (74.5), and long spacer (74.4) over spin-

dle shaft (74.6).

3.

Insert spindle shaft with bearings and spacers into

spindle housing (74.2) from the bottom.

4.

Install upper bearing (74.3) over shaft with the seal

facing up.

5.

Install short bearing spacer (74.7) over shaft.

6.

Install sheave (38) with key (74.10) on shaft.

Secure with washer (74.9) and nut (74.8) torque to

110 lbs-ft.

GEARBOX REPAIR

Read this entire section before starting any repair.

Many steps are dependent on each other.

Fill gearbox with SAE 80W or 90W gear lube until it

runs out the side level plug. Gearbox capacity is almost

4 pints.

Repair to this gearbox is limited to replacing bearings,

seals, and gaskets. Replacing gears, shafts, and a

housing is not cost effective. It is more economical to

purchase a complete gearbox if repair to anything other

than replacement of bearings, seals or gaskets is

required.

Inspect gearbox for leakage and bad bearings.

Leakage is a very serious problem and must be cor-

rected immediately.

Bearing failure is indicated by excessive noise and side

to side or end play in gear shafts.

Seal Replacement

Recommended sealant for gearbox repair is Perma-

tex

®

Aviation 3D Form-A-Gasket or equivalent.

Leakage can occur at the vertical or horizontal gaskets

and shaft seals.

Leakage at the horizontal shaft gasket or seal can be

repaired without removing the gearbox from the mower.

4

1/2 NC Flange lock nut

28

1/2 NC x1.5 HHCS GR5

29

1/2 NC x 1.75 HHCS GR5

38

Sheave

74.1. Spindle spacer

74.2. Housing, cast

74.3. Bearing, 1" sealed

74.4. Sleeve, 1.03 X 1.25 X 2.72

74.5. Bearing, 1"

74.6. Spindle shaft

74.7. Sleeve, 1.01 X 1.50 X .34

74.8. Nut, 5/8 NC lock

74.9. Washer, 5/8 SAE flat

74.10. Key, 1/4 X 1/4 X 1.0

74.11. Grease fitting

77. Blade kit (high suction)

78. Cap screw, 5/8 NF x 2.5 GR5

79. Bell washer, 5/8 x 2.5 x .25