30

Dealer Service

MAN1313 (3/3/2021)

13.

Slide spacer (12) over input shaft (3) and press

bearing onto input shaft (3), using a round tube of

the correct diameter and a hand press.

14.

Slide shim (13) over input shaft (3) and secure with

snap ring (10).

15.

Check input shaft end float by moving the input

shaft (3) by hand. If end float is higher than 0.012”,

insert shim between input shaft (3) and rear

bearing (7). Repeat until end float is less than

0.012”. Check rotational torque by hand. The

torque should be less than 2.2 lbs-inch.

16.

Check that the gear backlash is between 0.006”

and 0.016”. You should not have to adjust the

backlash.

17.

Press in input oil seal (19), using tube of correct

diameter. Be careful not to damage seal lip.

18.

Press oil cap (20) on to cover the rear of housing,

using a tube of the correct diameter.

19.

Check gearbox housing for leaks by plugging all

holes except one. Apply 4 psi compressed air and

immerse the gearbox in water to verify that there

are no leaks..

20.

Remove gearbox from water and dry off with

compressed air. Add SAE 80W or 90W EP oil until

it runs out of side level hole. Tighten all plugs.

Install Gearbox (Figure 24)

IMPORTANT:

Gearbox is heavy; do not attempt to

move without mechanical assistance.

1.

Install drive sheave (48) and key (71) on gearbox

output shaft.

2.

Install sleeve (49), washer (50), and castle nut (52)

on gearbox output shaft. Torque castle nut to 170

lb-ft. Install cotter pin (51) through castle nut and

gearbox output shaft.

3.

Slide gearbox onto gearbox stand. When gearbox

is installed on mower, dimension A (from the top of

mower deck to the center line of the drive pulley)

must be 2-3/4” (±1/8”).

This is a critical

dimension and must be carefully adjusted for

proper belt life.

Add or subtract shim washers

under idler sheave to align with drive sheave. See

Figure 25.

4.

Install carriage bolts (25) and new flange lock nuts

(8) through gearbox base. Torque nuts to 175 lb-ft.

5.

Install belt into drive sheave groove and route

around backside idler on idler arm. See Figure 17.

6.

Grasp belt with both hands between the left spindle

sheave and the idler arm. Pull on belt to rotate idler

arm and slip belt over left spindle sheave. Carefully

release belt, ensuring proper seat in left spindle

sheave groove. Ensure belt is properly seated in all

sheave grooves.

7.

Reinstall belt shields and retain with thumb screws.

8.

Install drive shield (35) over gearbox input shaft.

9.

Install flange head cap screws (36) through drive

shield and into gearbox housing. Carefully snug

hardware.

10.

Use SAE 80W or 90W gear lube to fill gearbox.

11.

Reinstall vent/dipstick (24) and reconnect driveline

to gearbox input shaft.

Figure 25

. Drive Sheave Installation

FILL GEARBOX

1.

Make sure vent/dipstick hole is clear. Fill gearbox

half-full with high quality gear oil that has a

viscosity index of 80W or 90W and an API service

rating of GL-4 or GL-5.

2.

Pour in one pint of gear oil. Wait five minutes, then

add additional gear oil until it just comes out of

gearbox side hole. Gearbox holds approximately 4

pints.

3.

Allow an additional five minutes for the oil to flow

through bearings, then make sure oil level is at

bottom side hole. Replace side plug. Install vent

plug.

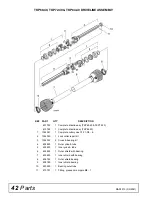

UNIVERSAL JOINT REPAIR

Figure 26

. U-Joint Exploded View

1. Yoke

2. Cup and bearings

3. Snap ring

4. Journal cross