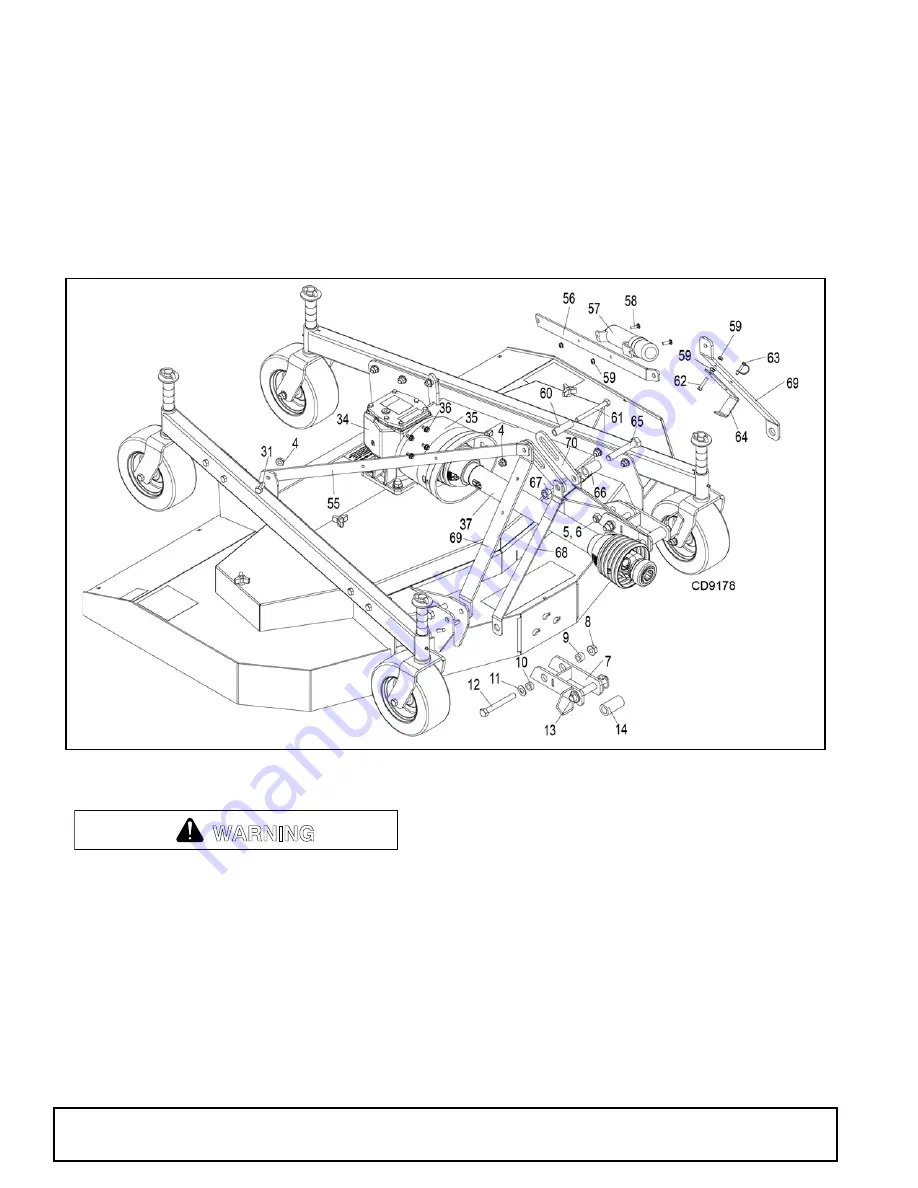

34

Assembly

MAN1313 (3/3/2021)

12.

Install 5/8NC x 3-1/2 cap screws (5) through deck

hitch plates behind mower lower hitch links (7) to

keep hitch links level. Retain with 5/8NC lock nuts

(6).

13.

Install quick hitch sleeves (14) over clevis pins (13)

in mower lower hitch links (7). Install mower quick

hitch a-frame bars (68) over the clevis pins on the

inside face of the mower lower hitch links. Retain

with included klik pins.

14.

Position top quick hitch sleeve (66) between

mower top hitch links (70). Align mower quick hitch

a-frame bars (68) on outside of top hitch links.

Ensure alignment of assembly using 3/4NC x 4-1/2

cap screw (65). Retain with ¾ NC lock nut (67).

Tighten then back off 1/4 – 1/2 turn to ensure

assembly moves up and down freely.

CAUTION!:

Pinch Hazard. Hands or fingers could be

pinched between quick hitch a-frame bars and rigid a-

frame bars on mower. Do not push on quick hitch a-

frame bars when mower is disconnected from tractor.

Figure 32

. Hitch Assembly

Connect PTO driveline directly to power unit

PTO shaft. Never use adapter sleeves or adapter

shafts. Adapters can cause driveline failures due to

incorrect spline or incorrect operating length and

can result in personal injury or death.

Driveshaft Installation

1.

Orient the driveline with the implement end toward

the mower gearbox. The implement end uses the

female profile tube (large), which is covered by the

smaller profile shield (plastic tube). Slide the QD

collar back and push the drive yoke onto the

gearbox input shaft. Make sure the QD is seated

securely in the groove of the gearbox shaft.

2.

The tractor end of the driveline uses the male

profile tube (small). The male profile is covered by

the larger profile shield (plastic tube). Slide the QD

collar back to ensure it operates smoothly.

Lubricate if necessary.

3.

Hang the driveline on the driveline holder.

4.

If your driveline came with tether chains, attach the

implement end chain to the gearbox input shield.

WARNING