31

Finding the causes of any troubles turned up and their remedy always demands extra attention and caution. Before starting

trouble-shooting, always pull the power supply plug.

In the following, some of the most frequent defects and their causes are listed. In case of any further defects, please call

your dealer.

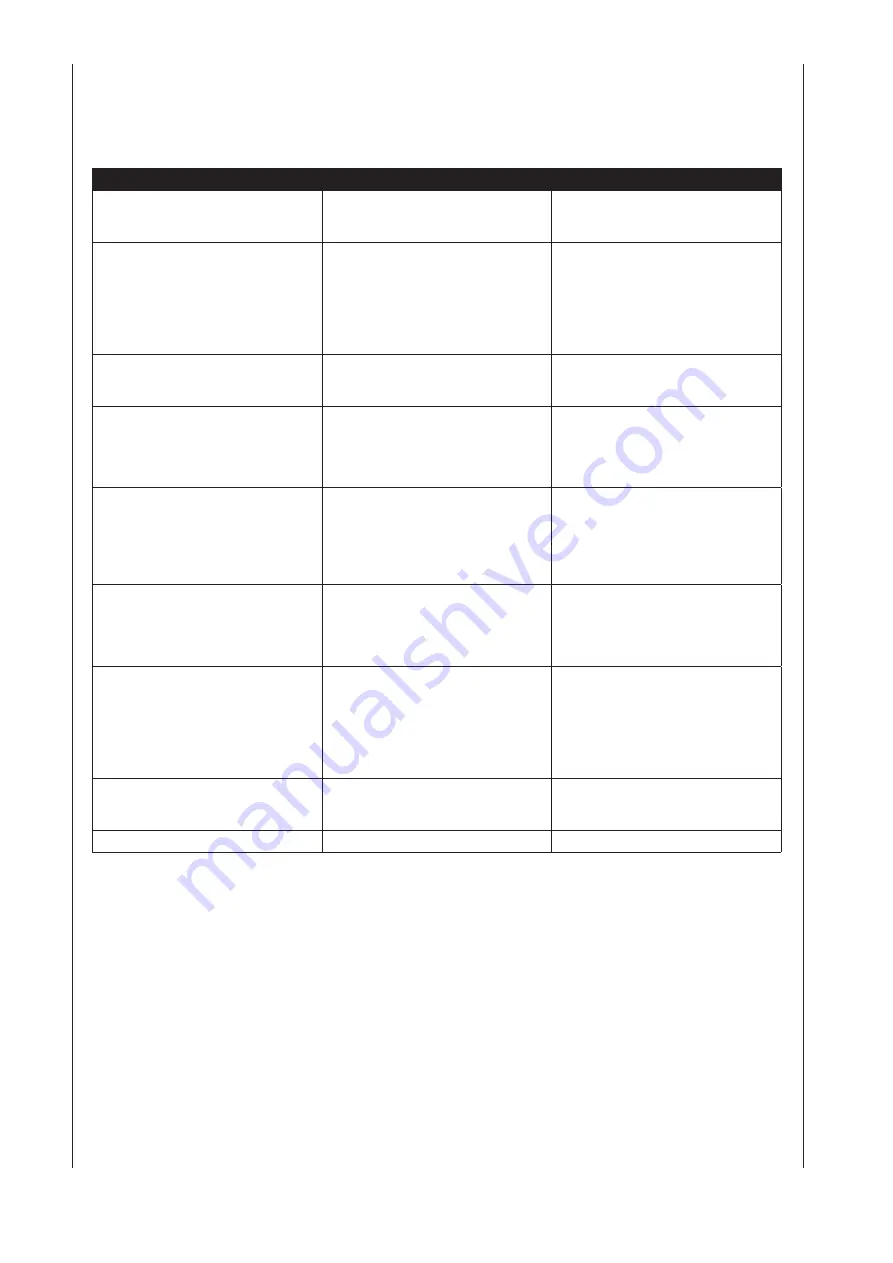

Problem

Possible Cause

Remedy

Machine cannot be switched on.

No power supply.

Carbon brush worn.

Check power supply.

Take machine to your service point.

Machine switches automatically off

during idle run.

No mains supply.

Check fuses.

Due to the integrated low-voltage

protection, the machine does not re-

start automatically. Upon return of the

voltage, the machine must be switched

on again.

Machine stops during planing.

Overload protection reacts due to blunt

knives, infeed too fast, or chip removal

too thick.

Before work is continued, replace

knives or let cool down the motor.

Response of the overload protection.

Too much chip removal

Too fast feed

Blunt knives

Before continuing work, replace the

knives or wait for the motor to cool

down.

Planed surface not smooth.

Infeed too fast.

Blunt knives.

Irregular feed.

Reduce infeed speed.

Replace knives.

Apply constand pressure and reduce

feed.

When thicknessing, chip ejection

obstructed (without dust extractor).

Chip removal too important.

Blunt knives.

Wood too humid.

Reduce chip removal.

Replace knives.

When surface planing, chip ejection

obstructed (without dust extractor)

Chip removal too important.

Infeed to fast.

Blunt knives.

Wood too humid.

Reduce chip removal.

Replace knives.

With surface planing and thicknessing,

chip ejection obstructed (with dust

extractor).

Suction performance too weak.

Use a dust extractor unit having an

air-flow rate at the suction connection

of at least 20 m/s.

Rpm drops during planing.

Chip removal too important.

Reduce chip removal.