28 | GB

Noise

Total noise values determined in accordance with EN

62841.

Sound pressure level L

pA

........................... 96,5 dB(A)

Uncertainty K

pA

.................................................... 3 dB

Sound power level L

WA

............................. 109,5 dB(A)

Uncertainty K

WA

.................................................... 3 dB

Wear hearing protection.

The effects of noise can cause a loss of hearing

The above-mentioned noise emission values were

measured in accordance with a standardised test pro-

cedure and can be used to compare one power tool

with another.

The above-mentioned noise emission values can also

be used for the preliminary assessment of exposure.

Warning:

• The noise emissions during the actual use of the

power tool may differ from the above-mentioned

values depending on the power tool being used, in

particular on the type of workpiece being processed.

• Try to keep emissions as low as possible, for ex-

ample by limiting your working time. In this regard,

all the operational cycle phases must be taken into

consideration (such as the times when the tool is

switched off or running idle).

7. Before starting the equipment

• Open the packaging and remove the device care-

fully.

• Remove the packaging material as well as the

packaging and transport bracing (if available).

• Check that the delivery is complete.

• Check the device and accessory parts for trans-

port damage.

• If possible, store the packaging until the warranty

period has expired.

ATTENTION

The device and packaging materials are not toys!

Children must not be allowed to play with plastic

bags, film and small parts! There is a risk of swal

-

lowing and suffocation!

• The equipment must be set up where it can stand

securely. Secure the machine on a workbench or a

base frame with 4 screws (not included in delivery)

using the holes on the fixed saw table (15).

• Pull out the pre-installed tilt protection (36) com-

pletely and secure it with an Allen key (D).

• All covers and safety devices have to be properly

fitted before the equipment is switched on.

• It must be possible for the blade to run freely.

• Furthermore, despite all precautions having been

met, some non-obvious residual risks may still re-

main.

• Residual risks can be minimised if the „safety in-

structions“ and the „Proper use“ are observed along

with the whole of the operating instructions.

• Do not load the machine unnecessarily: excessive

pressure when sawing will quickly damage the saw

blade, which results in reduced output of the ma-

chine in the processing and in cut precision.

• When cutting plastic material, please always use

clamps: the parts which should be cut must always

be fixed between the clamps.

• Avoid accidental starting of the machine: the operat-

ing button may not be pressed when inserting the

plug in an outlet.

• Use the tool that is recommended in this manual.

In doing so, your machine provides optimal perfor-

mance.

• Hands may never enter the processing zone when

the machine is in operation.

•

Release the handle button and switch off the ma

-

chine prior to any operations.

6. Technical data

AC motor ...................................... 220 - 240 V~ 50Hz

Power S1 .................................................... 1700 Watt

Operating mode ................................ S6 25%* 2000W

Idle speed n

0

...............................................4700 min

-1

Carbide saw blade ...................ø 216 x ø 30 x 2,6 mm

Number of teeth .......................................................24

Maximum tooth width of saw blade ....................3 mm

Swivel range ........................................-45° / 0°/ +45°

Mitre cut ...................................... 0° bis 45° to the left

Saw width at 90° .....................................340 x 65 mm

Saw width at 45° .....................................240 x 65 mm

Saw width at 2 x 45°

(double mitre cut)....................................240 x 38 mm

Protection class ...................................................II /

Weight ....................................................... ca. 11,9 kg

Laser class ................................................................2

Wavelength of laser .........................................650 nm

Laser output.................................................... < 1 mW

* S6, continuous operation periodic duty.

Identical duty cycles with a period at load followed by

a period at no load. Running time 10 minutes; duty

cycle is 25% of the running time.

The work piece must have a minimum height of 3

mm and a minimum width of 10 mm.

Make sure that the workpiece is always secured

with the clamping device.

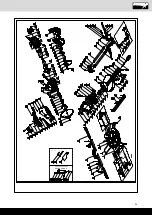

Summary of Contents for SL90LXU

Page 4: ...4 21 22 17 20 E E E 19 32 32a 32b 32b 16 17 18 15 5 29 34 31 33 30 28 C 6...

Page 20: ...20 DE...

Page 35: ...35...