GB | 29

• Position the angle stop (A) between the saw blade

(6) and the rotary table (14).

• Loosen the lock nut (26a).

• Adjust the adjusting screw (26) until the angle be-

tween the saw blade (6) and rotary table (14) is 90°.

• Re-tighten the lock nut (26a).

• Subsequently check the position of the angle indi-

cator. If necessary loosen the pointer (19) using a

Philips screwdriver, set to position 0° on the angle

scale (18) and re-tighten the retaining screw.

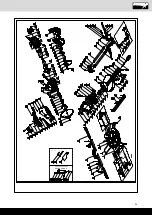

8.3 Crosscut 90° and turntable 0° (fig. 1/2/7)

In the case of cutting widths up to approx. 100 mm it

is possible to fix the traction function of the saw with

the set screw (20) in the rear position. In this position

the machine can be operated in cross cutting mode. If

the cutting width is over 100 mm then it is necessary

to ensure that the set screw (20) is loose and the ma-

chine head (4) can move.

Attention! For 90° crosscuts, the moveable stop rail

(16a) must be fixed in the inner position.

• Open the set screw (16b) for the moveable stop

rail (16a) and push the moveable stop rail (16a) in-

wards.

• The moveable stop rail (16a) must be locked in a

position far enough from the inner position that the

distance between the stop rail (16a) and the saw

blade (6) is no more than 8 mm..

• Before making the cut, check that the stop rail (16a)

and the saw blade (6) cannot collide.

• Re-tighten the set screw (16b).

• Move the machine head (4) to its upper position.

• Use the handle (1) to push back the machine head

(4) and fix it in this position if required (dependent on

the cutting width).

• Place the piece of wood to be cut at the stop rail

(16) and on the turntable (14).

• Lock the material with the clamping devices (7) on

the fixed saw table (15) to prevent the material from

moving during the cutting operation.

• Release the lock switch (3) and press the ON/OFF

switch (2) to start the motor.

•

With the drag guide (21) fixed in place (21)

:

use the handle (1) to move the machine head (4) stead-

ily and with light pressure downwards until the saw

blade (6) has completely cut through the work piece.

•

With the drag guide (21) not fixed in place (21):

pull the machine head (4) all the way to the front.

Lower the handle (1) to the very bottom by applying

steady and light downward pressure. Now push the

machine head (4) slowly and steadily to the very

back until the saw blade (6) has completely cut

through the work piece.

• When the cutting operation is completed, move the

machine head back to its upper (home) position and

release the ON/OFF button (2).

• When working with wood that has been processed

before, watch out for foreign bodies such as nails or

screws, etc.

• Before you press the ON/OFF switch check that the

saw blade is fitted correctly. Moving parts must run

smoothly.

• Before you connect the equipment to the power

supply make sure the data on the rating plate are

dentical to the mains data.

7.1 Checking the moving saw blade guard safety

device (5)

The saw blade guard protects against accidental con-

tact with the saw blade and from chips flying around.

Check function

To do so, fold the saw downwards:

• The saw blade guard must provide free access to

the saw blade without touching other parts.

• When folding the saw upwards into the starting

position, the saw blade guard must cover the saw

blade automatically.

8. Attachment and operation

8.1 Attaching the crosscut, drag and mitre saw

(fig. 1/2/4/5)

• In order to adjust the rotary table (14), loosen the

handle (11) approximately 2 turns and pull up the

latched position lever (35) with your index finger.

• Turn the rotary table (14) and pointer (12) to the de-

sired angle measurement on the scale (13) and use

the handle (11) to secure it.

• Pressing the machine head (4) lightly downwards

and removing the locking bolt (23) from the motor

bracket at the same time disengages the saw from

the lowest position.

• Swing the machine head (4) up.

• It is possible to secure the clamping devices (7) to

the left or right on the fixed saw table (15). Insert the

clamping devices (7) in the holes on the rear side

of the stop rail (16) and secure it with the star grip

screws (7a).

For 0°- 45° mitre cuts, the clamping device (7) must

only be mounted on the right side (see fig. 11-12).

• It is possible to tilt the machine head (4) a max. 45°

to the left by loosening the set screw (22).

• Workpiece supports (8) must always be secured

and used during work. Set the desired table size

by loosening the set screw (9). Then tighten the set

screw (9) again.

8.2 Precision adjustment of the stop for crosscut

90° (fig. 1/2/5/6)

• No stop angle included.

• Lower the machine head (4) and secure it using the

locking bolt (23).

• Loosen the set screw (22).

Summary of Contents for SL90LXU

Page 4: ...4 21 22 17 20 E E E 19 32 32a 32b 32b 16 17 18 15 5 29 34 31 33 30 28 C 6...

Page 20: ...20 DE...

Page 35: ...35...