-33-

M1109 Combo Lathe/Mill

O

PE

R

AT

IO

N

S

Setting RPM

When using the milling machine, determine the RPM

needed to cut your workpiece, and adjust the gear

change levers to achieve the closest RPM.

NOTICE

Never shift gears while lathe or mill is running; other-

wise, the gear teeth will be chipped or broken.

To determine and set the mill to the needed RPM, do

these steps:

1.

Select the cutting speed required for the material of

your workpiece using the table in

Figure 37

.

2.

Measure the diameter of your cutting tool in inches.

3.

Use the following formula to determine the needed

RPM for your operation:

(Cutting Speed x 4) / Tool Diameter = RPM

Note:

You will only be able to get an approximate

RPM value with the variable speed knob.

4.

Move the mill gearbox levers to the nearest milling

speed RPM.

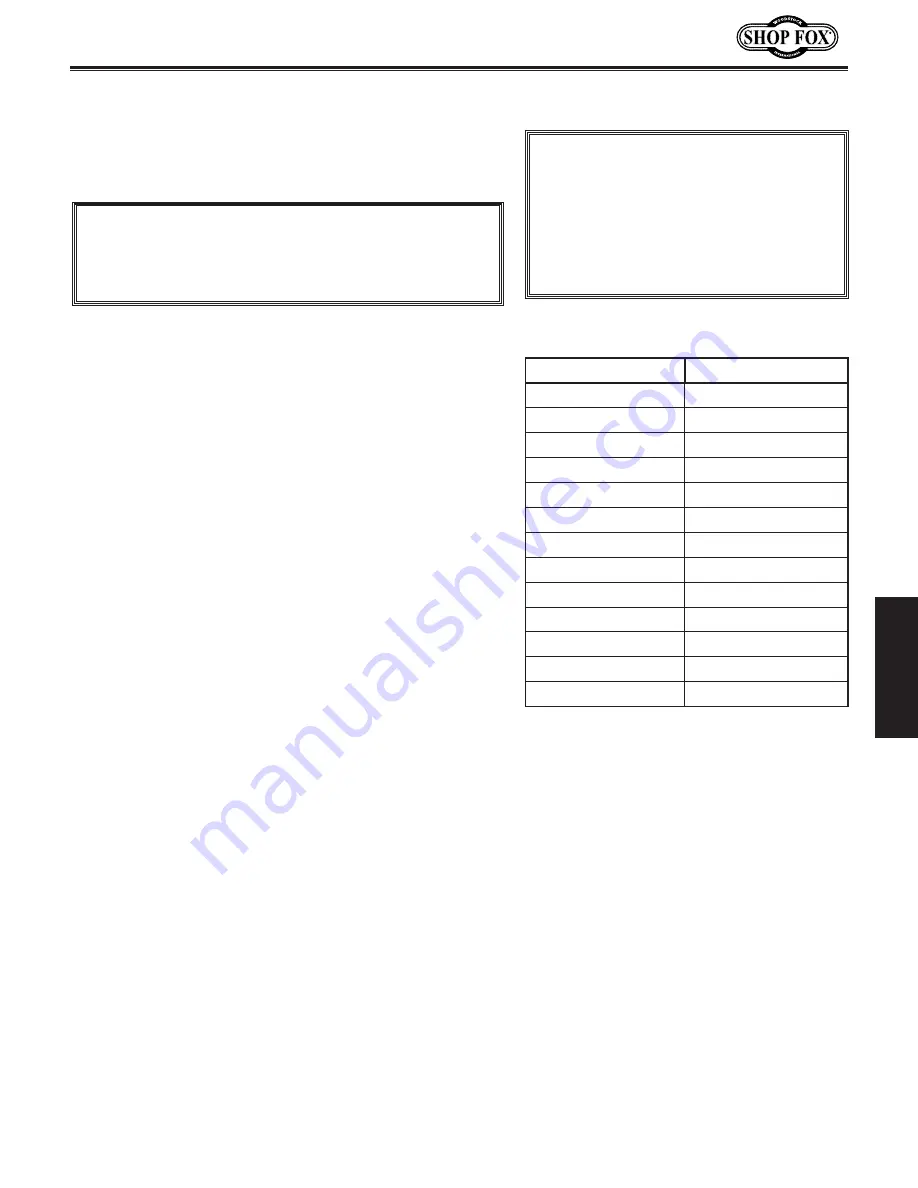

Cutting Speeds for High Speed Steel (HSS)

cutting tools:

Workpiece Material Cutting Speed (sfm)

Aluminum & alloys

300

Brass & Bronze

150

Copper

100

Cast Iron, soft

80

Cast Iron, hard

50

Mild Steel

90

Cast Steel

80

Alloy Steel, hard

40

Tool Steel

50

Stainless Steel

60

Titanium

50

Plastics

300-800

Wood

300-500

Figure 37.

High speed steel cutting chart.

Note:

Double the cutting speed for carbide

cutting tools. These values are a guideline

only. Refer to the MACHINERY'S HANDBOOK

for more detailed information.

NOTICE

Failure to follow RPM and Feed Rate

Guidelines will put undue strain on

moving parts, shorten tool life, poor

workpiece results and may threaten

operator safety from ejected parts or

broken tools.

Summary of Contents for M1109

Page 2: ... ...

Page 31: ... 29 M1109 Combo Lathe Mill OPERATIONS Change Gear Chart ...

Page 52: ... 50 M1109 Combo Lathe Mill PARTS Compound Rest and Tool Post Diagram 2500 Series Parts ...

Page 56: ... 54 M1109 Combo Lathe Mill PARTS Steady Rest and Follow Rest Diagram 3500 Series Parts ...

Page 69: ... 67 M1109 Combo Lathe Mill PARTS Notes ...

Page 73: ......

Page 74: ......