-25-

Model M1112 (For Machines Mfd. Since 12/20)

O

PE

R

ATIO

NS

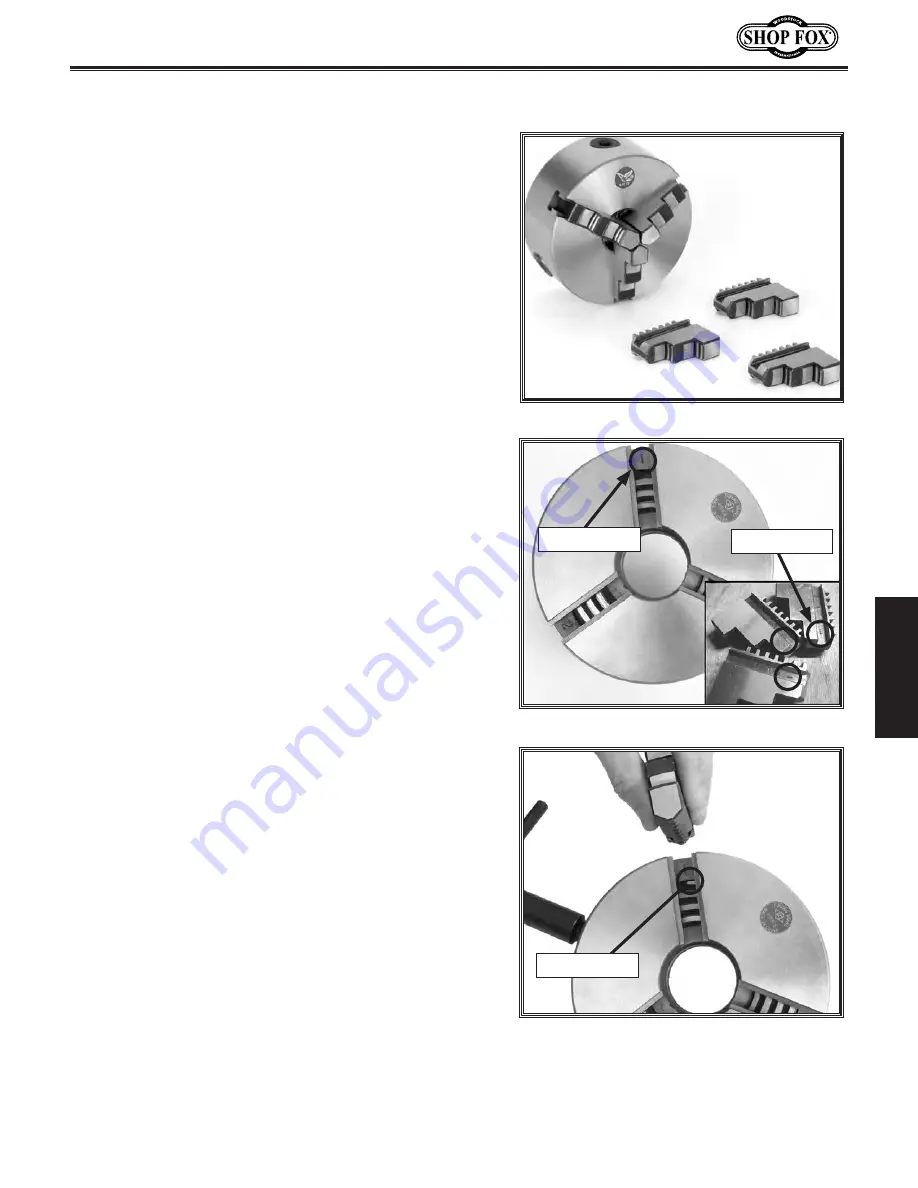

The three-jaw scroll chuck has removable hardened steel

jaws (

Figure

28). The outside of the jaws are used to hold

the workpiece from the outer diameter.

Numbered from 1–3, the jaws must be used in the

matching numbered jaw guides, see (

Figure

29).

Note:

The chuck need not be removed from the spindle to

swap the jaws.

To swap a set of jaws, do these steps:

1.

DISCONNECT LATHE FROM POWER!

2

. Place a piece of wood over the ways to protect them

from potential damage.

3

. Turn the chuck key counterclockwise and back the

jaws out.

4

. Clean the jaw mating surfaces and apply a film of

white lithium grease to the mating surfaces.

5

. Set the old jaws aside in a safe place free of

moisture and abrasives.

6.

Rotate the chuck key clockwise until you see the tip

of the scroll-gear lead thread just begin to enter jaw

guide #1 (see

Figure

30).

7.

Insert jaw #1 into jaw guide #1 and hold the jaw

against the scroll gear.

8.

Rotate the chuck key clockwise one turn to engage

the tip of the scroll-gear lead thread into the jaw.

Pull on the jaw now and it should be locked into the

jaw guide.

9

. Repeat the steps on the remaining jaws.

•

If installed correctly, all three jaws will converge

together at the center of the chuck.

•

If the jaws do not come together, repeat this pro-

cedure until they do.

Swapping Jaws

Figure

28

.

Chuck and jaw selection.

Figure

29

.

Jaw guide number.

Figure

30

.

Lead thread on scroll gear.

Jaw Guide #1

Lead Thread

Jaw Numbers