-19-

Model M1112 (For Machines Mfd. Since 12/20)

SE

TU

P

Tailstock

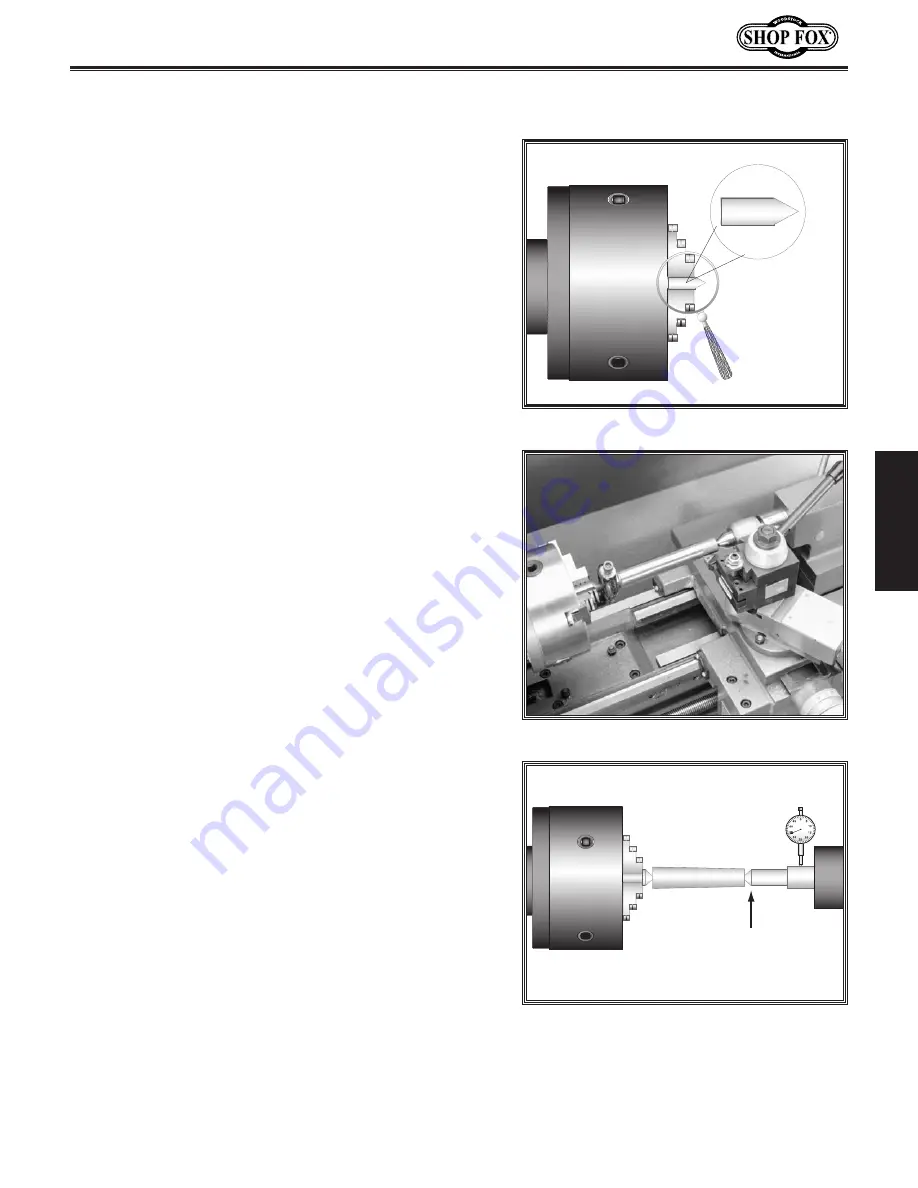

Figure

16

.

Finished dead center.

Figure 17.

Bar stock mounted on centers.

Figure 18.

Adjusting for headstock end

taper.

Looking down from above.

Move tailstock toward

back of lathe

1

/

2

the

amount of taper.

The tailstock alignment was set at the factory with the

headstock. However, we recommend that you take the

time to ensure that the tailstock is aligned to your own

desired tolerances.

To align the tailstock, do these steps:

1.

Center drill a 6'' long piece of bar stock on both

ends. Set it aside for use in

Step 4

.

2.

Make a dead center by turning a shoulder to make

a shank. Flip the piece over in the chuck and turn a

60° point (s

ee Figure

16)

.

As long as it remains in

the chuck, the point of your center will be accurate

to the spindle axis.

Note:

Keep in mind that the point will have to be

refinished whenever it is removed and returned to

the chuck.

3.

Place the live center in your tailstock.

4.

Attach a lathe dog to the bar stock from

Step 1

and

mount it between the centers

(as shown in

Figure

17).

5.

Turn approximately 0.010" off the diameter.

6.

Mount a dial indicator so that the plunger is on the

tailstock barrel (

Figure

18).

7.

Measure the stock with a micrometer. If the stock is

wider at the tailstock end, the tailstock needs to be

moved toward the cutter the amount of the taper

(

Figure

18).

— If the stock is thinner at the tailstock end, the

tailstock needs to be moved away from the

operator by half the amount of the taper (

Figure

19).