-27-

Model M1112 (For Machines Mfd. Since 12/20)

O

PE

R

ATIO

NS

7.

Make fine adjustments by slightly loosening one jaw

and tightening the opposing jaw until the workpiece

is precisely aligned.

8.

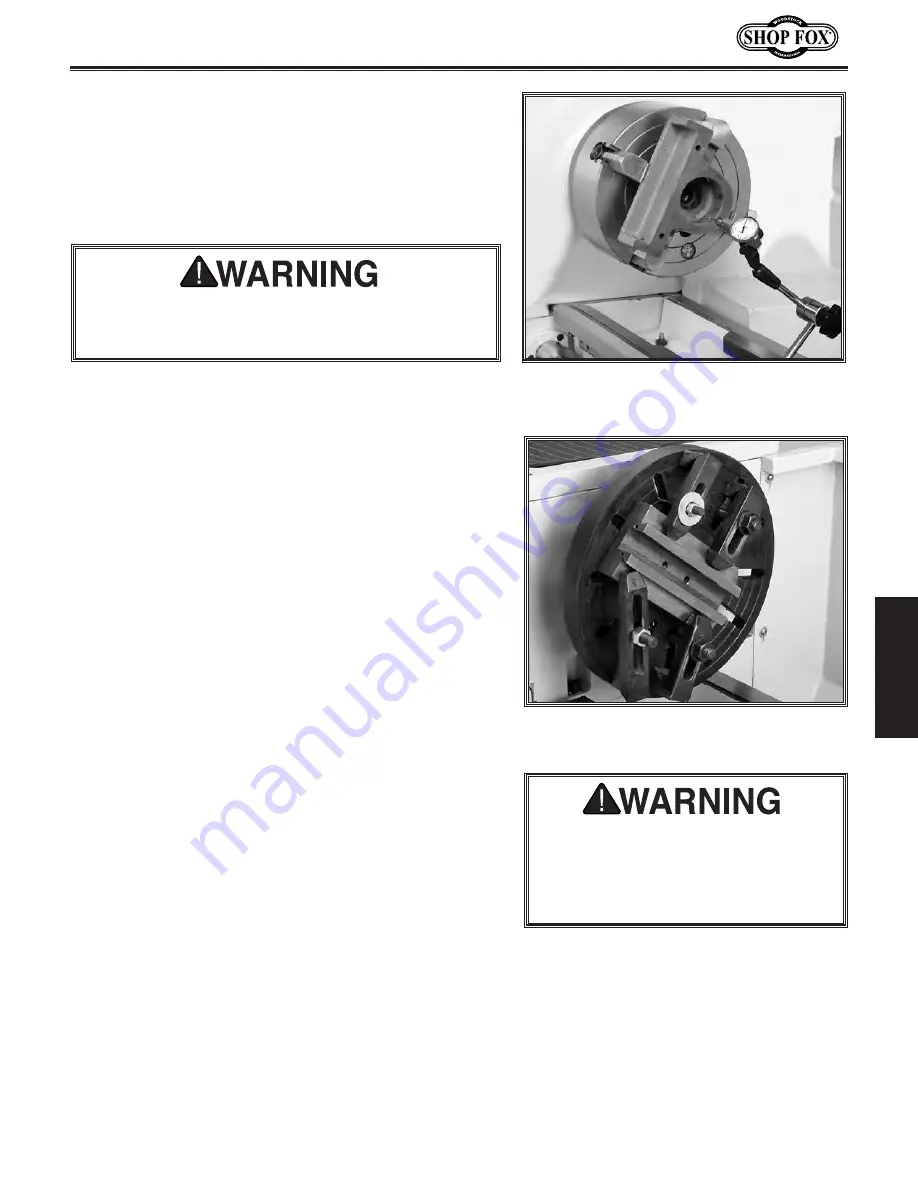

Use a dial indicator to fine-tune your adjustments

(see

Figure

33), and use a lower RPM when

machining heavy eccentric workpieces.

Figure

33

.

Centering workpiece.

PROJECTILE HAZARD! Use a lower RPM when machining

heavy eccentric workpieces. Otherwise, the workpiece

can be ejected by the chuck and cause serious injury.

The faceplate can be used to turn non-cylindrical parts or

for off-center turning by clamping the workpiece to the

faceplate.

To install the faceplate, refer to the

Mounting Chuck or

Faceplate

procedures on

Page 22

to mount the faceplate.

To load a workpiece, do these steps:

1

. Support the workpiece on the faceplate with a

minimum of three independent clamping devices

(see

Figure

34). Failure to follow this step may lead

to deadly injury to yourself or bystanders. Take into

account rotation and the cutting forces applied to

the workpiece when clamping to the faceplate.

Make

sure your clamping application will not fail!

Note:

Depending on the workpiece, some additional

support or counter-balance may be needed.

2.

Slide the tailstock to the workpiece.

3.

Lock the tailstock and then turn the tailstock quill so

the dead center makes contact with the center point

of your workpiece.

4.

Lock the tailstock quill when sufficient pressure is

applied to hold the workpiece in place.

Note:

Use a lower RPM when machining heavy

eccentric workpieces.

5.

Clamp the workpiece securely and counter-balance

as needed.

Faceplate

Figure

34

.

Faceplate with properly

clamped workpiece in four locations.

Use a minimum of three independent

clamping devices when turning eccentric

workpieces. Failure to provide adequate

clamping will cause workpiece to eject,

which may cause serious injury or death.